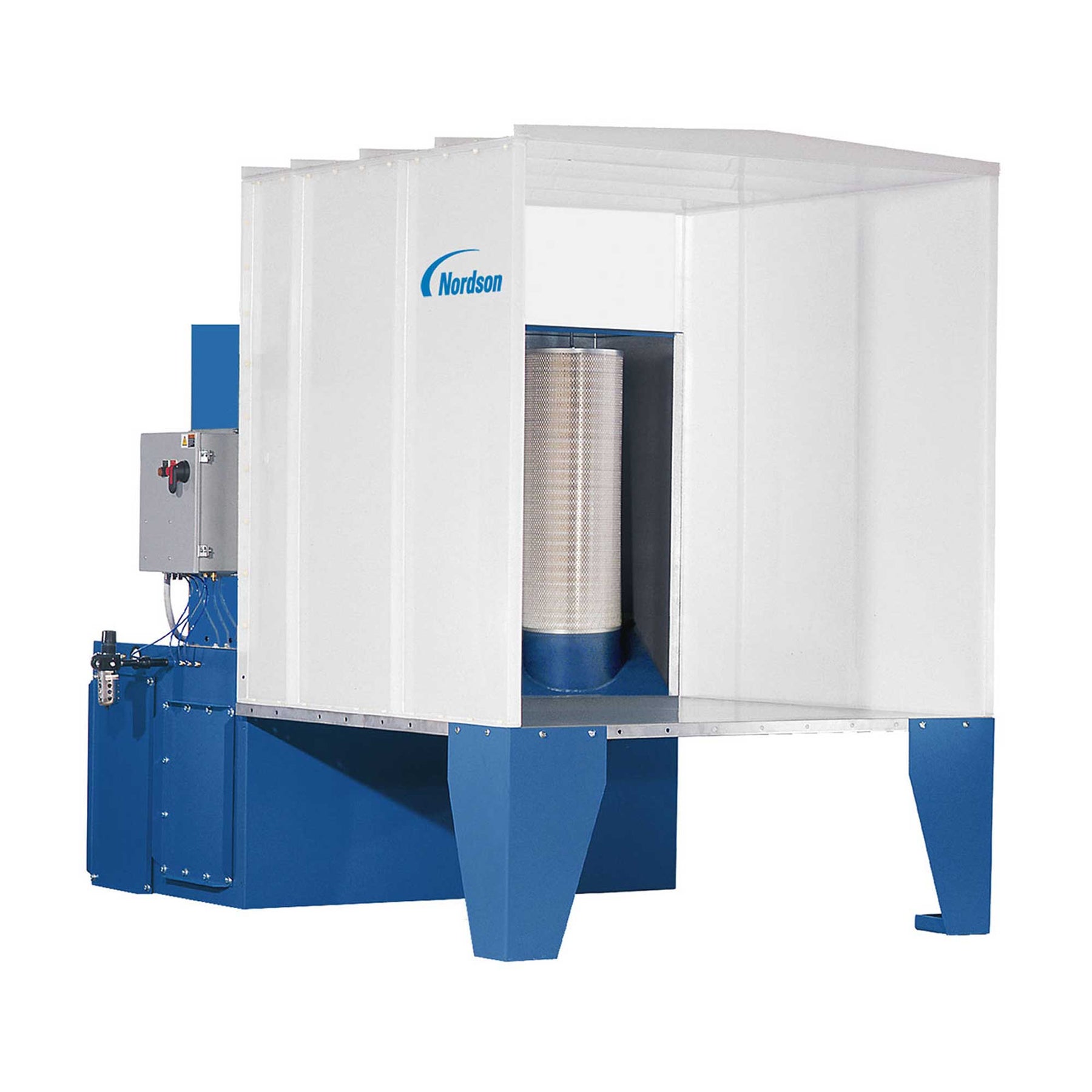

Nordson

Econo-Coat II Powder Spray Booth

Compact powder spray booth/recovery system for batch powder coating

Perfect size for coating medium-size parts

The Nordson Econo-Coat II powder spray booth system is ideal for coating wheels and other automotive parts, test panels for new color evaluation, or any other parts that fit within its 5’ high by 5’ wide by 5’ deep work envelope.

- Small footprint for maximum space utilization

- High-performance polypropylene canopy with clear roof

- Reverse-pulse filter cartridge cleaning for peak performance and long service life

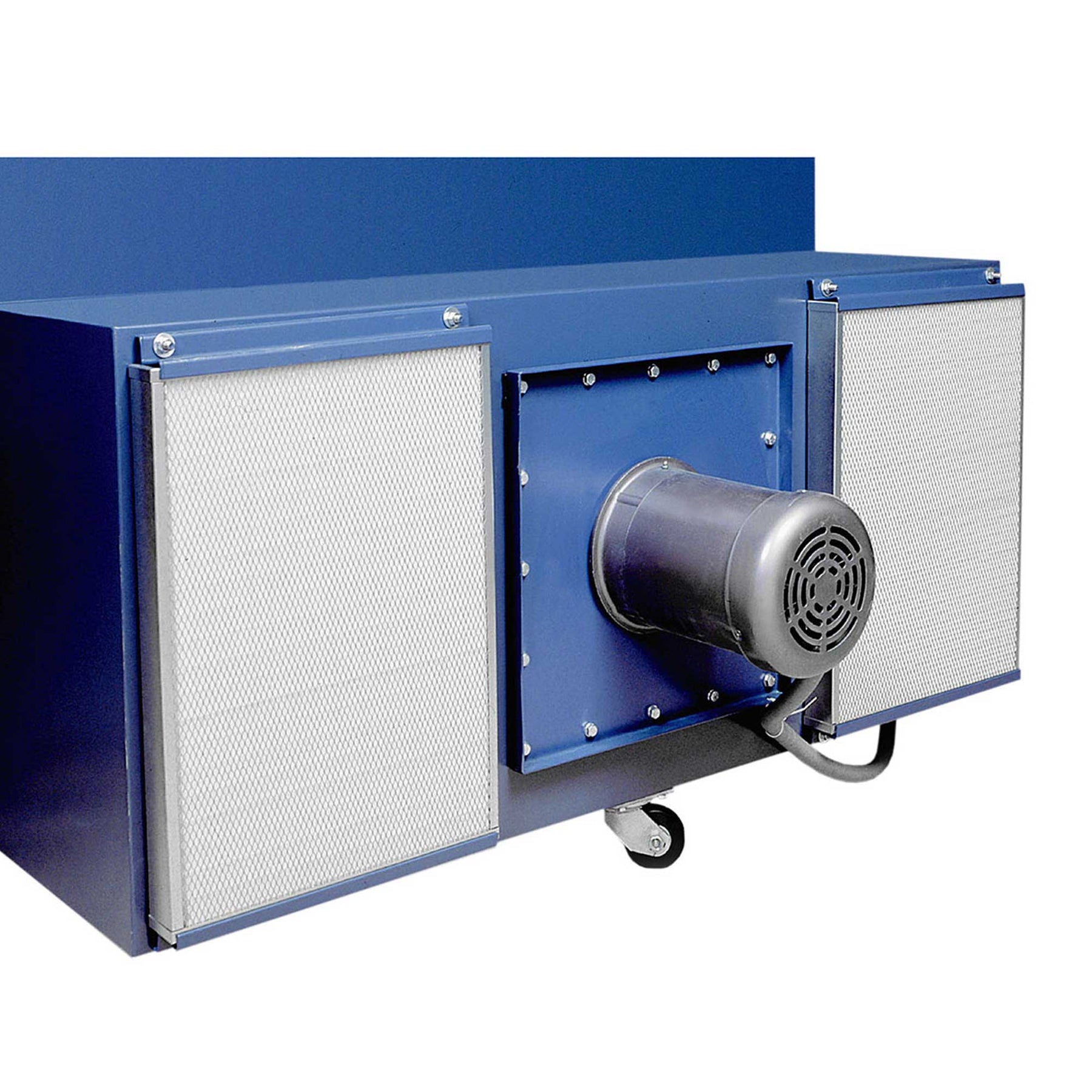

- Final filters returns clean air to the workplace

- 460VAC, 3-phase, 60Hz standard, with other voltages optional

- UL508 control panel for safety and ease of use

Proven cartridge-filter technology

Nordson cartridge-filter powder recovery systems do not require expensive ductwork and explosion venting. Air used to contain and recover powder overspray passes through primary cartridge filters and final filters, and is then exhausted as clean air.

Primary cartridge filters are cleaned using a reverse-pulse of air for maximum operating efficiency and extended filter life.

Safe, simple operation

The Econo-Coat II booth control panel includes:

- Main power switch

- Booth exhaust start and stop switches

- Cartridge-filter blow-down timer

- Filter pressure safety interlock switch

Optional powder application equipment

The Econo-Coat II powder spray booth is designed for use with Nordson application equipment, such as the Encore® LT, XT or HD mobile powder spray systems.

Together, this package provides versatile, economical, high-performance operation to meet a variety of powder coating requirements.