Pneumatic systems are the lifeblood of many industries, powering everything from assembly lines to heavy machinery. To ensure these systems operate at peak performance, the installation of Air Line FRLs (Filter, Regulator, Lubricator) is crucial. In this comprehensive guide, we'll delve into the importance of proper Air Line FRL installation, step-by-step instructions, common pitfalls to avoid, and maintenance best practices.

Understanding Air Line FRLs

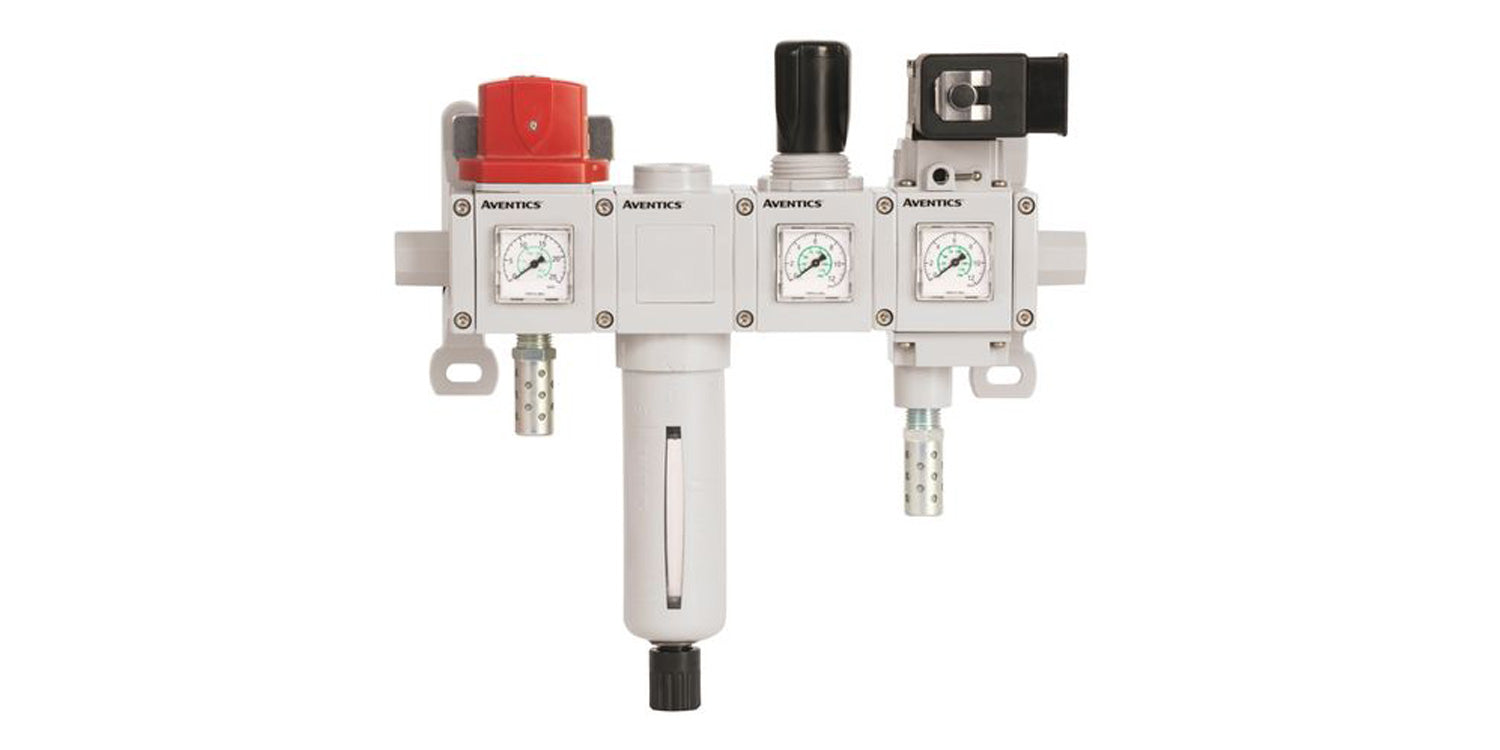

Before we dive into installation procedures, let's briefly understand what Air Line FRLs are and why they matter. An Air Line FRL is a combination of three components: the filter, regulator, and lubricator. These components work together to ensure the quality and consistency of compressed air supplied to pneumatic systems.

The filter removes contaminants such as dirt, oil, and moisture from the compressed air, preventing damage to downstream components. The regulator controls the air pressure, maintaining it at a consistent level for optimal system operation. The lubricator adds a fine mist of lubricating oil to the air, extending the life of pneumatic components and reducing friction.

The Significance of Proper Installation

Proper Air Line FRL installation is paramount for several reasons:

- Efficiency: Correctly installed FRLs ensure that only clean, regulated, and lubricated air reaches your pneumatic components. This efficiency translates into smoother operation and increased productivity.

- Component Longevity: Contaminants in compressed air can lead to premature wear and tear of pneumatic components. By filtering and lubricating the air, FRLs significantly extend the lifespan of your equipment.

- Cost Savings: Reduced downtime and fewer component replacements lead to substantial cost savings in the long run. Investing in proper FRL installation pays off.

Step-by-Step Guide to FRL Installation

Now, let's get down to the nitty-gritty of Air Line FRL installation:

- Step 1: Choosing the Right Location

- Select a clean, dry, and cool location away from direct sunlight.

- Ensure easy access for maintenance.

- Step 2: Mounting the FRL

- Use sturdy brackets or mounts to secure the FRL unit.

- Ensure it's level and stable.

- Step 3: Connecting the Air Supply

- Connect the compressed air supply line to the FRL inlet.

- Use proper fittings and sealants to prevent leaks

- Step 4: Connecting the Output

- Attach the downstream equipment to the FRL outlet.

- Use appropriate fittings and hoses.

- Step 5: Adjusting the Regulator

- Set the desired air pressure using the regulator.

- Refer to equipment specifications for optimal pressure settings.

Common Mistakes to Avoid

Despite the straightforward installation process, several common mistakes can compromise the effectiveness of your Air Line FRLs. Avoid these pitfalls:

- Neglecting Maintenance: FRLs require regular maintenance, including filter replacement and lubricator refilling. Neglecting this can lead to system inefficiencies.

- Improper Sizing: Using undersized or oversized FRL units can result in inadequate filtration or excessive pressure drops. Always choose the right size for your system.

- Incorrect Placement: Placing FRLs in hot or dusty environments can lead to accelerated wear and reduced performance. Keep them in a clean, controlled area.

Maintenance and Best Practices

To ensure your pneumatic system continues to operate smoothly, follow these maintenance and best practices:

- Regularly inspect and replace filters and lubricators as needed.

- Monitor air pressure and adjust the regulator as required.

- Train your team on FRL maintenance and safety protocols.

- Consider investing in automated monitoring systems for real-time data on air quality.

Proper Air Line FRL installation is the cornerstone of efficient pneumatic systems. By following the step-by-step guide and avoiding common mistakes, you can enjoy increased efficiency, longer equipment life, and significant cost savings. Remember that regular maintenance is key to sustaining these benefits.

At HMFT, we pride ourselves on more than just selling top-quality products. We boast a team of technical experts intimately familiar with the products we offer. Beyond that, our trained service technicians are equipped with the skills and experience to handle installation, repairs, and routine maintenance, ensuring our customers enjoy the full potential and longevity of their purchases. Your satisfaction, backed by our expertise, is our commitment.