Blogs

Powder Coating

The Importance of Proper Surface Preparation in Powder Coating

Proper surface preparation is crucial in powder coating to ensure adhesion and avoid defects like peeling or bubbling. Clean, degrease, and remove rust for a quality finish.

Powder Coating

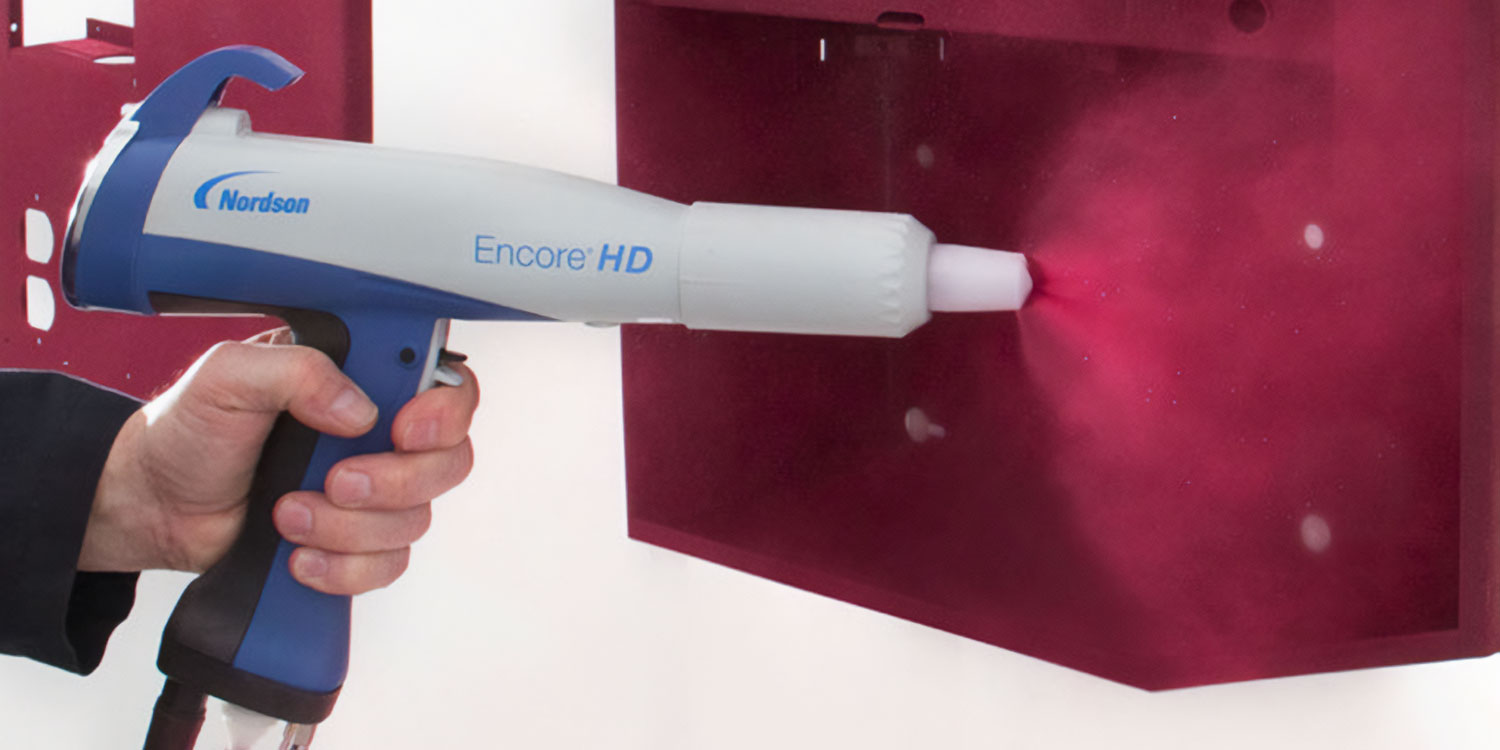

The Use of Powder Coating Equipment in Coating Large-Scale Industrial Machinery

Powder coating extends machinery life by creating a durable finish that resists chipping, fading, and corrosion. HMFT provides advanced Nordson equipment for efficient, high-quality results.

Powder Coating

The Effects of Temperature and Humidity on Powder Coating Processes

Temperature and humidity are crucial in powder coating. Ideal temperatures (65-80°F) ensure proper flow and curing, while humidity (40-60%) affects adhesion and finish quality.

Powder Coating

The Cost Savings of Using Powder Coating Equipment Over Traditional Liquid Coating Methods

Powder coating enhances durability and appearance while offering significant cost savings. It reduces waste, speeds up production, and minimizes maintenance, leading to lower expenses.

Powder Coating

How To Properly Maintain And Troubleshoot Powder Coating Equipment

Powder coating is a popular finishing method for metal. Proper maintenance of Nordson equipment is crucial for efficiency; regular cleaning and following guidelines ensure longevity.