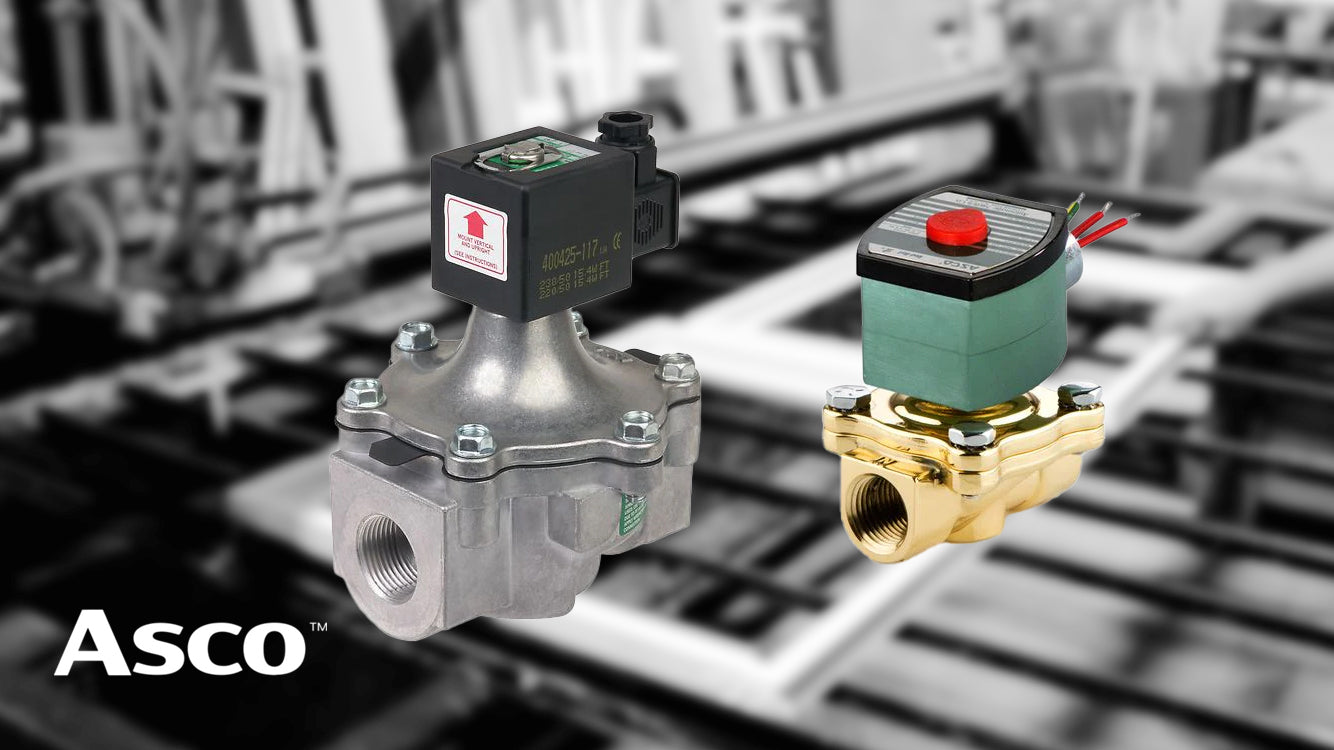

In today’s fast-paced window manufacturing industry, automation isn’t just a luxury—it’s a necessity. From coating and sealing to cooling and cleaning, automated systems are transforming production lines, boosting efficiency, and reducing costs. At the heart of these systems are ASCO solenoid valves, known for their precision, reliability, and adaptability. At HMFT, we’re proud to distribute ASCO solenoid valves across Canada, helping window manufacturers streamline their operations and stay ahead of the competition. Let’s dive into how these valves are revolutionizing automation in window production.

The Role of Automation in Window Manufacturing

Automation has become a cornerstone of modern window manufacturing processes. By replacing manual tasks with automated systems, manufacturers can achieve:

- Higher Productivity: Automated systems work faster and more consistently than manual operations.

- Improved Quality: Precision control ensures uniform application of coatings, adhesives, and sealants.

- Reduced Costs: Automation minimizes material waste and lowers labour expenses.

- Enhanced Safety: Automated systems reduce worker exposure to hazardous materials and high-pressure environments.

ASCO solenoid valves play a crucial role in enabling these benefits by providing reliable fluid control in pneumatic and hydraulic systems.

How ASCO Solenoid Valves Streamline Automation

ASCO solenoid valves are designed to integrate seamlessly into automated systems, offering precise control over fluid flow. Here’s how they contribute to smoother operations in window manufacturing:

1. Precise Fluid Control

In processes like coating and sealing, consistency is everything. ASCO solenoid valves regulate the flow of paints, adhesives, and sealants with pinpoint accuracy, ensuring even application every time. This reduces material waste and eliminates the need for costly rework due to uneven finishes.

2. Reliable Pneumatic Systems

Pneumatic systems are widely used in automated machinery for tasks like frame assembly and material handling. ASCO solenoid valves control the air supply in these systems, enabling smooth and precise movements that improve production speed and accuracy.

3. Efficient Cooling and Cleaning

Cooling glass during tempering or cleaning frames before coating requires precise water or air flow management. ASCO solenoid valves provide the control needed to optimize these processes, reducing water and energy consumption while maintaining high-quality results.

4. Seamless Integration with PLCs

ASCO solenoid valves are compatible with programmable logic controllers (PLCs), making it easy to incorporate them into existing automated setups. Their fast response times ensure that your systems operate efficiently without delays or interruptions.

The Benefits of Using ASCO Solenoid Valves in Automation

Window manufacturers who integrate ASCO solenoid valves into their automated systems can expect several advantages:

- Durability: ASCO valves are built to withstand harsh environments, including high pressures and corrosive fluids.

- Low Maintenance: Their robust design reduces downtime caused by wear-and-tear or valve failure.

- Sustainability: By optimizing fluid usage, these valves help manufacturers reduce waste and meet environmental goals.

- Scalability: Whether you’re running a small shop or a large factory, ASCO solenoid valves can be customized to fit your specific needs.

The Future of Automation in Window Manufacturing

The demand for smarter, faster production lines is only growing as customers expect higher-quality products at competitive prices. ASCO solenoid valves are paving the way for more advanced automation solutions that help manufacturers meet these demands while improving sustainability and profitability.

Your Partner in Automation Success

If you’re ready to take your window manufacturing operations to the next level with advanced automation solutions, ASCO solenoid valves are the perfect choice. At HMFT, we’re here to help you find the right products for your unique needs while providing reliable support every step of the way.

Contact us today to learn how ASCO solenoid valves can transform your production line—and let’s build a smarter future together!

FAQ

Can ASCO solenoid valves handle high-pressure applications?

- Yes! ASCO valves are designed to operate under high-pressure conditions without compromising performance or durability.

Are these valves compatible with Industry 4.0 systems?

- Absolutely. ASCO solenoid valves integrate easily with smart manufacturing setups for remote monitoring and predictive maintenance.

How do these valves improve energy efficiency?

- By optimizing fluid flow and reducing waste, ASCO solenoid valves help lower energy consumption across various processes like cooling, cleaning, and coating.

What maintenance is required for ASCO solenoid valves?

- These valves require minimal maintenance thanks to their robust design. Regular inspections ensure long-term reliability without frequent replacements.

Can HMFT assist with valve integration?

- Yes! At HMFT, we provide expert guidance on selecting the right ASCO solenoid valves for your needs and offer support during installation and integration into your systems.