When it comes to liquid finishing processes, safety is non-negotiable. Industrial facilities often deal with flammable liquids, volatile organic compounds (VOCs), and potentially explosive atmospheres, making it critical to use equipment that meets stringent safety standards. This is where ASCO explosion-proof solenoid valves come into play. Designed to perform reliably in hazardous environments, these valves provide precise fluid control while ensuring the highest levels of safety.

The Importance of Explosion-Proof Valves in Liquid Finishing

Liquid finishing processes often involve the use of flammable materials like solvent-based paints, coatings, and cleaning agents. These materials can emit vapours that, when mixed with air in certain concentrations, create a highly combustible atmosphere. In such environments, even a small spark or heat source can trigger an explosion.

Explosion-proof solenoid valves are specifically engineered to prevent such incidents. They are designed to:

- Contain any internal sparks or heat generated during operation.

- Isolate the electrical components from the surrounding hazardous atmosphere.

- Ensure reliable performance even in extreme conditions.

For facilities handling flammable liquids and vapours, using explosion-proof equipment isn’t just a best practice—it’s often a legal requirement under standards like ATEX (Atmosphères Explosibles) and NEC (National Electrical Code).

Key Features of ASCO Explosion-Proof Solenoid Valves

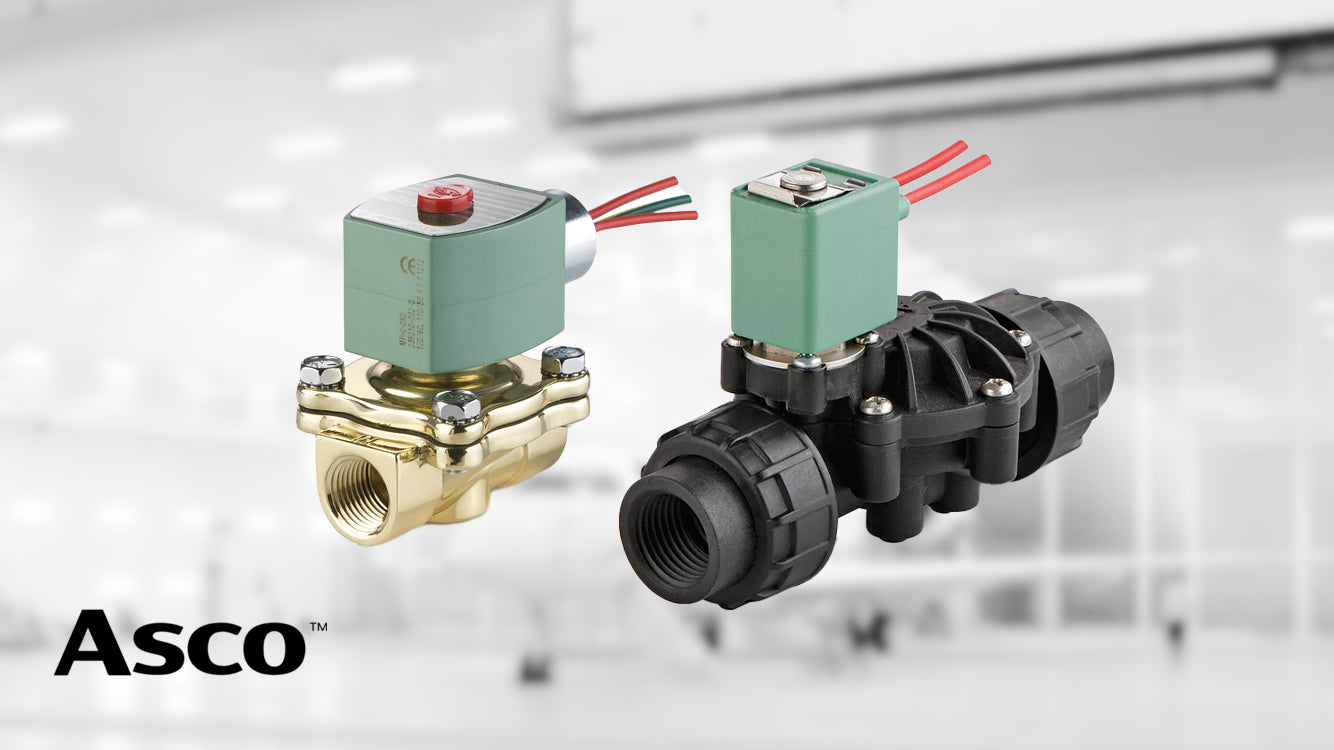

ASCO’s explosion-proof solenoid valves are trusted across industries for their robust design and reliable performance. Here’s what makes them ideal for hazardous liquid finishing environments:

1. ATEX and CSA Certifications

ASCO valves meet international safety standards for use in explosive atmospheres. They are certified for Class I, Division 1 locations under NEC standards and ATEX Zone 1 environments in Europe.

2. Encapsulated Coils

The coils in ASCO explosion-proof valves are fully encapsulated to prevent any sparks or heat from escaping into the surrounding environment. This ensures safe operation even when handling volatile fluids.

3. Corrosion-Resistant Materials

Many liquid finishing processes involve aggressive chemicals. ASCO valves are available in corrosion-resistant materials like stainless steel and brass to handle harsh environments without compromising safety.

4. Wide Temperature Range

ASCO explosion-proof valves are designed to operate in a broad temperature range, ensuring reliable performance even in extreme conditions commonly found in industrial finishing facilities.

5. Low-Power Options

ASCO offers low-power solenoid valves that reduce energy consumption while maintaining high performance. This is particularly beneficial for facilities looking to improve energy efficiency without sacrificing safety.

Applications of ASCO Explosion-Proof Valves in Liquid Finishing

Explosion-proof solenoid valves play a critical role in various stages of the liquid finishing process:

1. Paint Circulation Systems

These valves regulate the flow of solvent-based paints and coatings from storage tanks to spray booths, ensuring precise delivery without risking ignition.

2. Solvent Recovery Systems

Solvent recovery systems often operate in hazardous atmospheres due to the presence of VOCs. ASCO valves ensure safe fluid transfer during the recovery and recycling process.

3. Cleaning Systems

Automated cleaning systems for spray guns and lines use flammable cleaning agents that require careful handling. Explosion-proof valves provide safe and reliable control over these fluids.

4. Booth Airflow Control

In spray booths where flammable vapours may accumulate, ASCO valves help regulate airflow systems to maintain safe operating conditions.

Benefits of Using ASCO Explosion-Proof Valves

By incorporating ASCO explosion-proof solenoid valves into your liquid finishing operations, you can achieve several key benefits:

- Enhanced Safety: Prevent ignition of flammable vapours and protect workers and equipment from potential explosions.

- Regulatory Compliance: Meet safety standards like ATEX, NEC, and CSA to avoid fines or shutdowns due to non-compliance.

- Reliable Performance: Operate consistently even in extreme temperatures or corrosive environments and minimize downtime with durable construction and long service life.

- Energy Efficiency: Reduce energy costs with low-power valve options and support sustainability goals without compromising safety.

HMFT’s Role: Your Trusted Partner for Safe Finishing Solutions

At HMFT, we understand the unique challenges faced by industrial manufacturers engaged in liquid finishing processes. That’s why we partner with industry leaders like ASCO to provide cutting-edge solutions tailored to your needs.

Our team offers:

- Expert guidance on selecting the right explosion-proof solenoid valves for your application.

- Installation support to ensure proper integration with your existing systems.

- Ongoing maintenance services to keep your equipment operating safely and efficiently.

With HMFT by your side, you can focus on delivering high-quality finishes while maintaining a safe working environment.

Conclusion

Safety should never be an afterthought—especially in hazardous liquid finishing environments where flammable materials are part of daily operations. ASCO explosion-proof solenoid valves provide the peace of mind you need by combining precision fluid control with robust safety features.

Ready to upgrade your facility with reliable, certified explosion-proof solutions? Contact HMFT today to learn how we can help you implement ASCO solenoid valves that meet your safety and operational requirements.

FAQ

What certifications do ASCO explosion-proof solenoid valves have?

- ASCO valves are certified under ATEX (Zone 1) and NEC (Class I, Division 1) standards for use in hazardous locations.

Can these valves handle aggressive chemicals?

- Yes! ASCO offers corrosion-resistant materials like stainless steel and brass for compatibility with aggressive fluids used in liquid finishing processes.

Are there energy-efficient options available?

- Absolutely! ASCO provides low-power solenoid valve models that reduce energy consumption while maintaining high performance.

What industries commonly use ASCO explosion-proof valves?

- These valves are widely used in automotive manufacturing, aerospace coating facilities, industrial equipment finishing plants, and any operation involving flammable liquids or vapours.

How can HMFT assist with implementing these solutions?

- HMFT provides expert consultation, installation support, and ongoing maintenance services to ensure your ASCO solenoid valves operate safely and efficiently within your system.

By choosing ASCO explosion-proof solenoid valves and partnering with HMFT, you’re investing not only in safety but also in long-term operational success!