In the power generation industry, efficiency and reliability are paramount. One often overlooked component that plays a crucial role in maintaining these qualities is the lube-oil system. At the heart of many such systems are IMO 3-screw pumps, which offer significant long-term benefits in reducing maintenance costs. Let's explore how these pumps contribute to cost-effective power plant operations.

Superior Design for Longevity

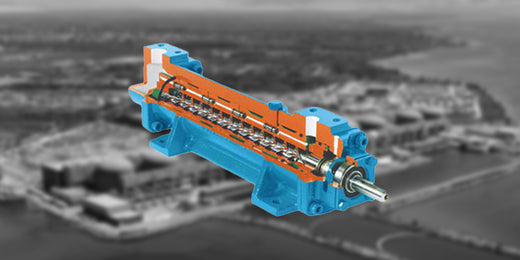

IMO 3-screw pumps are engineered with durability in mind. Their robust construction ensures longevity and reliability, significantly reducing downtime and maintenance costs over time. This design philosophy translates into fewer replacements and repairs, allowing power plants to operate continuously without frequent interruptions.

Consistent Performance, Less Wear

One of the key advantages of IMO 3-screw pumps is their ability to provide a steady, pulsation-free flow. This consistent performance is crucial for maintaining the health of critical machinery in power plants. By delivering a smooth flow of lubricant, these pumps reduce wear and tear on both themselves and the equipment they service, extending the lifespan of the entire lubrication system.

Handling High Viscosity Fluids

Power plants often deal with lubricants of varying viscosities, especially in different temperature conditions. IMO 3-screw pumps excel in handling a wide range of viscosities, making them versatile for various power generation applications. This adaptability means less need for specialized pumps, reducing inventory costs and simplifying maintenance procedures.

Energy Efficiency Translates to Cost Savings

These pumps are designed to provide maximum efficiency with low power consumption. In the long run, this energy efficiency translates to significant cost savings for power plants. Lower power consumption not only reduces operational costs but also contributes to the overall efficiency of the power generation process.

Minimal Wear and Tear

The design of IMO 3-screw pumps minimizes contact between rotating and stationary parts, reducing friction and wear. This inherent feature means that these pumps require less frequent maintenance and have a longer operational life. For power plants, this translates to lower replacement costs and reduced frequency of maintenance activities.

Quiet Operation for Better Work Environment

While not directly related to maintenance costs, the low noise levels of IMO 3-screw pumps contribute to a better working environment. This can indirectly lead to cost savings by improving worker productivity and reducing the need for expensive noise reduction measures in the plant.

Preventive Maintenance Made Easy

The simplicity and reliability of IMO 3-screw pumps make preventive maintenance straightforward. Regular inspections and routine maintenance tasks are less complex and time-consuming compared to other pump types. This ease of maintenance ensures that potential issues are caught early, preventing costly breakdowns and extending the pump's service life.

Conclusion

Incorporating IMO 3-screw pumps in power generation lube-oil systems is a strategic decision that pays dividends in the long run. Their robust design, consistent performance, and low maintenance requirements contribute significantly to reducing overall operational costs. By choosing these pumps, power plants can ensure reliable operation, minimize downtime, and achieve substantial savings over the lifetime of their equipment.

At HMFT, we not only provide top-quality IMO 3-screw pumps but also offer comprehensive support to ensure you get the most out of your investment. Our factory-trained technicians are available to service and repair these pumps, ensuring they operate at peak efficiency throughout their lifespan. Additionally, we stock major and minor repair kits for these pumps, allowing for quick and efficient maintenance when needed. Trust HMFT to keep your power generation operations running smoothly and cost-effectively.