In the world of power generation, turbine efficiency and reliability are paramount to maintaining consistent output and avoiding costly downtime. At the heart of every well-functioning turbine lies an often-overlooked hero: the lubrication system. These systems ensure that bearings, gears, and other critical components receive proper lubrication under varying operational conditions. At HMFT, we've seen firsthand how the right pressure relief valve can make all the difference in optimizing these systems, and Fulflo relief valves stand out as exceptional solutions for this demanding application.

The Critical Role of Lubrication Systems in Turbine Operation

Turbines, whether steam, gas, or hydro, rely on precision-engineered lubrication systems to:

- Reduce friction between moving parts

- Dissipate heat from bearings and other components

- Prevent premature wear and equipment failure

- Extend the operational life of expensive turbine components

- Maintain optimal efficiency during varying load conditions

These systems must deliver the right amount of oil at the correct pressure regardless of operational conditions—a seemingly simple task that becomes increasingly complex during startup, shutdown, and load fluctuations.

Common Challenges in Turbine Lubrication Systems

Turbine lubrication systems face several significant challenges that can compromise performance and reliability:

- Pressure Fluctuations: During startup, shutdown, and load changes, pressure spikes can occur in lubrication systems.

- System Protection: Without proper pressure relief, pumps and other components risk damage from overpressure conditions.

- Heat Generation: Inefficient pressure control can create excess heat in the lubrication system.

- Noise and Vibration: Conventional relief valves often chatter during pressure fluctuations, creating noise and potentially damaging vibrations.

- Maintenance Issues: Many relief valves require frequent adjustments and maintenance.

These challenges demand a solution that offers reliable, consistent performance—exactly what Fulflo relief valves provide.

How Fulflo Relief Valves Transform Turbine Lubrication Systems

Fulflo valves employ a unique guided piston design that offers several distinct advantages for turbine lubrication applications:

1. Unmatched Stability During Pressure Fluctuations

Unlike ordinary direct-acting relief valves, Fulflo guided piston valves are less responsive to transient pressure surges. This crucial design difference eliminates the tendency to pound, squeal, or chatter during the pressure variations that naturally occur in turbine operation.

This stability is particularly valuable during turbine startup and shutdown sequences when lubrication system pressures can fluctuate significantly. The sliding piston concept ensures smooth, reliable performance without the disruptive chatter that plagues conventional relief valves.

2. Precise Pressure Control

Fulflo valves are designed to operate reliably at pressures from as low as 2 PSI to as high as 1000 PSI. This wide operating range makes them suitable for various locations within turbine lubrication systems, from main pump discharge to bearing supply lines.

The flow-modulating design provides proportional pressure control, ensuring that system pressures remain within acceptable limits even during transient conditions. This precision helps maintain optimal oil flow to critical turbine components.

3. Energy Efficiency Through Design

The Fulflo valve reduces velocities through all but the controlling interface of the valve, minimizing system power loss. For turbine operators focused on efficiency, this means less energy wasted in the lubrication system and more power available for electricity generation.

In large industrial turbines, even small efficiency improvements in auxiliary systems like lubrication can translate to significant energy savings over time.

4. Superior Fluid Compatibility

Turbine oils vary in viscosity and composition, particularly as operating temperatures change. Fulflo valves operate effectively with all types of liquids across the full range of viscosities, including the various hydraulic oils used in turbine lubrication systems.

This versatility ensures consistent performance regardless of oil temperature or condition, a critical factor in maintaining reliable turbine operation.

Real-World Benefits for Turbine Operators

Implementing Fulflo relief valves in turbine lubrication systems delivers several tangible benefits:

- Enhanced Reliability: By eliminating chatter and providing stable pressure control, Fulflo valves help prevent lubrication failures that could lead to catastrophic turbine damage.

- Reduced Maintenance: The simple, robust design of Fulflo valves requires minimal maintenance compared to conventional relief valves that need frequent adjustments.

- Lower Operating Costs: Through improved energy efficiency and reduced maintenance requirements, Fulflo valves contribute to lower overall operating costs for turbine systems.

- Extended Equipment Life: Proper pressure control protects pumps and other lubrication system components from damage, extending their operational life and reducing replacement costs.

- Quieter Operation: The elimination of valve chatter creates a more pleasant working environment and reduces stress on system components.

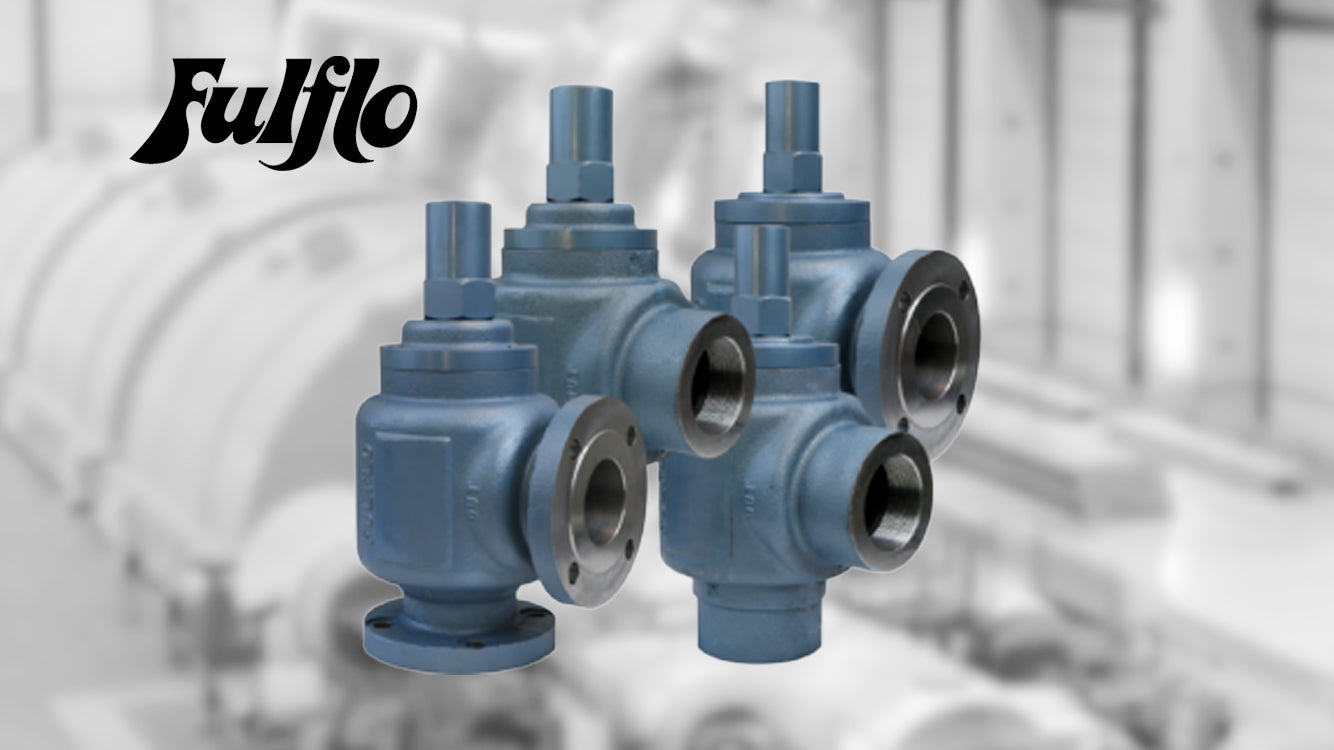

Selecting the Right Fulflo Valve for Your Turbine Application

When choosing a Fulflo valve for turbine lubrication systems, several factors should be considered:

- Valve Sizing: For optimal performance, select a valve size that matches the pipe to which it will be connected. A properly sized valve ensures adequate flow capacity while minimizing over-pressure.

- Material Selection: Depending on the environment and fluid properties, Fulflo valves are available in brass, cast iron, steel, and stainless steel. For standard turbine lubrication systems, brass or steel versions are typically sufficient.

- Pressure Range: Select a valve with the appropriate spring for your system's operating pressure. Fulflo valves offer various spring options to accommodate different pressure requirements.

- Connection Type: Choose between threaded connections or flanged options based on your system's requirements and maintenance preferences.

Implementation Best Practices

To maximize the benefits of Fulflo valves in turbine lubrication systems:

- Install in an Accessible Location: While Fulflo valves require minimal maintenance, positioning them for easy access simplifies periodic inspections.

- Proper Mounting: Fulflo valves can be mounted in any position, providing flexibility in system design and layout.

- Regular Inspection: Though low-maintenance, periodic inspection of valve function ensures continued optimal performance.

- Correct Pressure Setting: Set the cracking pressure high enough to permit normal system operation while ensuring the over-pressure remains within system limitations.

Conclusion

In the demanding world of turbine operation, reliable lubrication systems are essential for maintaining efficiency and preventing costly failures. Fulflo relief valves, with their unique guided piston design, provide the stable, chatter-free performance that turbine lubrication systems require.

At HMFT, we recognize that even small improvements in auxiliary systems can deliver significant benefits to overall turbine performance. By implementing Fulflo relief valves in your turbine lubrication systems, you can enhance reliability, reduce maintenance requirements, and improve operational efficiency.

Contact HMFT today to learn more about how Fulflo valves can optimize your turbine lubrication systems and help you maintain peak performance in your power generation operations.

FAQ Section

- Q: What makes Fulflo valves different from conventional relief valves for turbine applications?

- A: Fulflo valves use a guided piston design that eliminates chatter during pressure surges—a common problem with conventional valves that can damage turbine lubrication systems.

- Q: Can Fulflo valves handle the varying viscosities of turbine oils at different temperatures?

- A: Yes, Fulflo valves operate effectively with liquids across the full range of viscosities, making them ideal for turbine oils that may change consistency with temperature variations.

- Q: What pressure ranges can Fulflo valves accommodate in turbine lubrication systems?

- A: Fulflo valves operate reliably from as low as 2 PSI to as high as 1000 PSI, covering the full range of pressures found in turbine lubrication systems.

- Q: Are Fulflo valves suitable for both new turbine installations and retrofits?

- A: Absolutely. The versatile design and various connection options make Fulflo valves suitable for both new installations and upgrades to existing lubrication systems.

- Q: How often do Fulflo valves require maintenance in turbine applications?

- A: Fulflo valves require minimal maintenance compared to conventional relief valves. Periodic inspection is recommended, but adjustments are rarely needed due to their stable operation.

- Q: Are Fulflo valves positive shut-off valves?

- A: No, Fulflo valves are not designed to be positive shut-off valves and will pass a minimal amount of leakage before reaching the set pressure. This characteristic is actually beneficial in many turbine lubrication applications.