Introduction

In the realm of industrial pumping solutions, IMO Three-Screw Pumps stand as a beacon of efficiency and reliability. Designed to deliver high performance in a myriad of applications, these pumps are a staple in many industries. Understanding their mechanism and benefits is paramount for industry professionals aiming to harness their full potential.

Understanding the Mechanism

At the heart of IMO Three-Screw Pumps lies a simplistic yet ingenious working principle. Essentially, these pumps consist of three intertwined screws that rotate in unison within a precisely machined casing. The rotation creates chambers that carry the fluid from the inlet to the outlet, ensuring a continuous flow.

The primary screw, known as the power screw, drives the two secondary screws, ensuring synchronized movement. The meticulous design of the casing and screws ensures minimal leakage and high efficiency, making these pumps a preferred choice for many industrial applications.

Benefits of Using IMO Three-Screw Pumps

IMO Three-Screw Pumps boast a plethora of benefits, making them an attractive option for a multitude of industrial operations. One of the major advantages is their ability to provide a steady, pulsation-free flow, which is crucial for processes requiring precision and consistency.

Furthermore, their robust construction ensures longevity and reliability, reducing the downtime and maintenance costs over time. The design also allows for quiet operation, a benefit that enhances the workplace environment.

Applications Across Industries

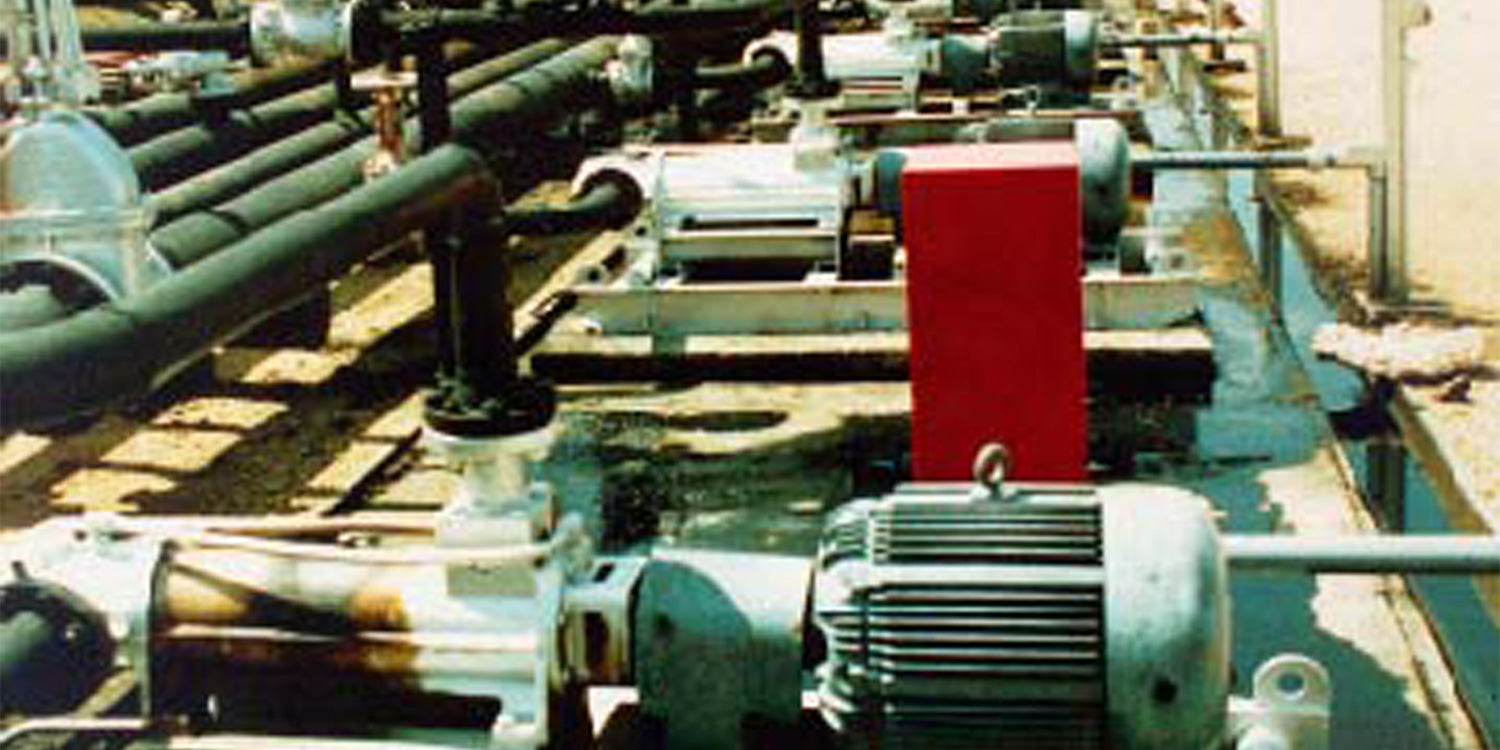

The versatility of IMO Three-Screw Pumps is showcased by their wide range of applications across various industries. Whether it’s the transfer of fuels in the petroleum industry or handling of chemicals in a processing plant, these pumps prove to be indispensable.

Their ability to handle different viscosities and maintain a consistent flow makes them a go-to solution in many sectors including marine, hydraulic, and power generation among others.

Maintenance and Troubleshooting

Like any industrial equipment, the performance and longevity of IMO Three-Screw Pumps are heavily influenced by regular maintenance and timely troubleshooting. Adopting a routine maintenance schedule, such as regular inspections for wear and tear, lubrication, and ensuring the alignment is correct, goes a long way in prolonging the pump’s life.

Equipped with basic troubleshooting knowledge, operators can quickly identify and rectify common issues, ensuring minimal disruption to operations.

IMO Three-Screw Pumps encapsulate a blend of simplicity, efficiency, and versatility, making them a prized asset in the industrial sector. By understanding their mechanism, benefits, and maintenance practices, industry professionals can significantly optimize their operations, ensuring a higher return on investment.

At HMFT, we pride ourselves on more than just selling top-quality products. We boast a team of technical experts intimately familiar with the products we offer. Beyond that, our trained service technicians are equipped with the skills and experience to handle installation, repairs, and routine maintenance, ensuring our customers enjoy the full potential and longevity of their purchases. Your satisfaction, backed by our expertise, is our commitment.