Chocolate production is as much a science as it is an art. From the smooth texture of a chocolate bar to the glossy finish on truffles, every step requires precision. One of the biggest challenges in chocolate manufacturing is managing its high viscosity, especially during processes like conching, tempering, and molding. At HMFT, we’ve seen how Roper Pumps have become a trusted solution for tackling these challenges, ensuring efficiency and quality in chocolate production.

The Complexity of Pumping Chocolate

Chocolate is not just any fluid—it’s a delicate, non-Newtonian substance with unique properties that make it difficult to handle:

- Temperature Sensitivity: Chocolate must stay within a precise temperature range. Overheating can degrade its quality, while cooling can cause solidification, leading to blockages.

- High Viscosity: The thick consistency of chocolate requires pumps that can handle viscous materials without clogging or losing efficiency.

- Shear Sensitivity: Excessive shear forces can alter the texture and flavour of chocolate by breaking down its structure.

- Abrasive Nature: Ingredients like cocoa solids and sugar can wear down pump components over time.

These challenges demand specialized equipment designed specifically for chocolate processing—and that’s where Roper Pumps excel.

Why Roper Pumps Are Perfect for Chocolate Production

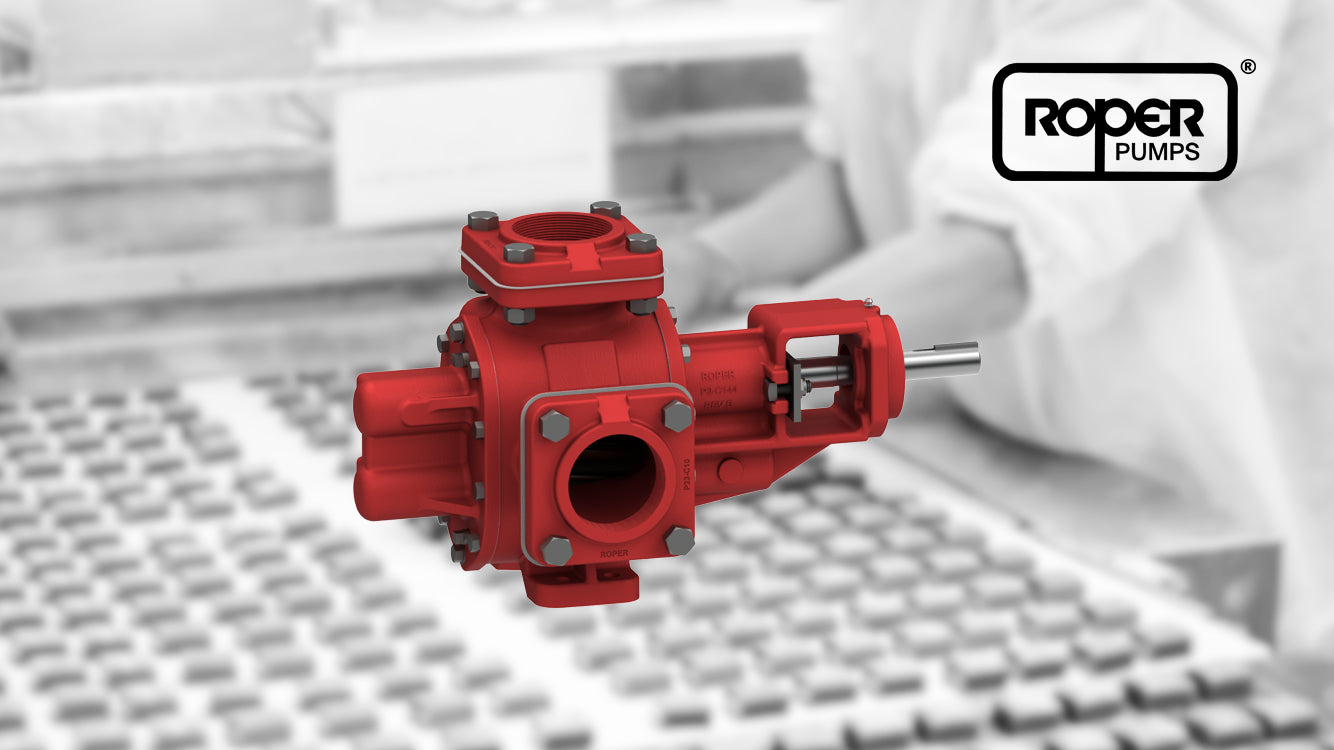

Roper Pumps are engineered to address the unique demands of chocolate manufacturing, offering solutions that ensure smooth operations while preserving product quality. Here’s how they do it:

1. Low-Shear Operation

Roper gear pumps operate with low shear forces, which helps maintain the integrity of chocolate during transfer. This is crucial for preserving the texture and flavour profile that consumers expect.

2. Temperature Control with Heating Jackets

Chocolate’s viscosity is highly dependent on temperature. Roper Pumps can be equipped with heating jackets to maintain an optimal temperature range, preventing solidification and ensuring consistent flow throughout the process.

3. Durable Components for Abrasive Fluids

The abrasive nature of chocolate ingredients can wear down standard pump components. Roper Pumps feature hardened internals and durable materials like stainless steel or cast iron, ensuring long-lasting performance even under harsh conditions.

4. Easy-to-Clean Design

Chocolate tends to coat internal surfaces, leading to potential blockages and inefficiencies. Roper Pumps are designed with easy-to-clean components, minimizing downtime for maintenance and ensuring hygienic operations that meet food safety standards.

5. Versatility for Various Chocolate Products

Whether it’s liquid chocolate for enrobing or thicker mixtures for moulding, Roper Pumps can handle a wide range of viscosities and applications thanks to their customizable configurations and precise flow control capabilities.

Applications of Roper Pumps in Chocolate Manufacturing

| Process | Pump Feature | Benefit |

|---|---|---|

| Conching | Low-shear operation | Maintains texture and flavour during aeration and mixing processes. |

| Tempering | Heating jackets | Keeps chocolate at the ideal temperature to stabilize cocoa butter crystals. |

| Enrobing & Coating | Consistent flow control | Ensures uniform coating on candies and bars without interruptions. |

| Molding & Depositing | Durable internals | Handles thick chocolate mixtures without clogging or wear-and-tear issues. |

| Ingredient Mixing | Versatile configurations | Accommodates different viscosities for smooth blending of ingredients. |

The Future of Chocolate Production with Roper Pumps

As consumer demand for high-quality chocolates grows, manufacturers need reliable equipment that can handle the complexities of production without compromising quality or efficiency. Roper Pumps are well-suited to meet these demands by offering:

- Customizable solutions for various applications in chocolate processing.

- Advanced features like heating jackets and low-shear operation to maintain product integrity.

- Durable designs that minimize maintenance costs and extend equipment lifespan.

With over 50 years of experience in food-grade applications, Roper Pumps have become a trusted partner for chocolate manufacturers worldwide.

Conclusion

At HMFT, we’re proud to distribute Roper Pumps in Canada, helping chocolate manufacturers overcome the challenges of high-viscosity fluids with innovative pumping solutions. Whether you’re producing artisanal truffles or large-scale chocolate bars, Roper Pumps ensure your operations run smoothly while delivering consistent quality.

Ready to upgrade your chocolate processing equipment? Contact HMFT today to learn more about how Roper Pumps can transform your production line.

FAQ

Q: What makes Roper Pumps suitable for high-viscosity fluids like chocolate?

A: Roper Pumps feature low-shear operation, heating jackets for temperature control, and durable materials that handle thick, abrasive fluids without clogging or wear.

Q: Can these pumps handle temperature-sensitive processes?

A: Yes! With optional heating jackets, Roper Pumps maintain optimal temperatures to prevent solidification and ensure consistent flow during production.

Q: How do these pumps minimize maintenance requirements?

A: Easy-to-clean designs reduce downtime for cleaning, while durable components like hardened internals resist wear from abrasive ingredients like cocoa solids.

Q: Are these pumps customizable for different applications?

A: Absolutely! Roper offers versatile configurations tailored to specific needs like conching, tempering, enrobing, or moulding.

Q: How do I know if a Roper Pump is right for my operation?

A: Contact HMFT! Our team will assess your specific needs and recommend the best pump solution for your chocolate production process.