In the world of chemical manufacturing, the challenge of efficiently moving thick, sticky, or paste-like materials can be a major headache. Whether you're dealing with adhesives, heavy oils, or high-solids content slurries, traditional pumping methods often fall short—resulting in wasteful material loss, frustrating flow inconsistencies, or even complete system failures. That's where Graco's Check-Mate pumps come in, offering a game-changing approach to handling high-viscosity chemicals with remarkable efficiency.

The Viscosity Challenge in Chemical Manufacturing

Moving highly viscous materials presents several unique obstacles that standard pumps simply weren't designed to handle:

- Flow resistance increases exponentially with viscosity

- Cavitation occurs when standard pumps create vacuum pockets

- Material shearing can alter critical chemical properties

- Pump stalling happens when motors can't overcome material resistance

- Incomplete container evacuation leads to costly material waste

The consequences? Production delays, compromised product quality, excessive material waste, and inflated operational costs that directly impact your bottom line.

Traditional Transfer Methods: Why They Fall Short

Conventional pumping technologies often struggle with high-viscosity materials for several reasons:

Centrifugal Pumps

These velocity-dependent pumps create fast-moving fluid streams that work well for water-like substances but lose efficiency dramatically as viscosity increases. When handling thick materials, they:

- Consume excessive energy

- Generate unwanted heat that can affect chemical properties

- Deliver inconsistent flow rates

- Often fail to self-prime with viscous materials

Gear Pumps

While better suited for thickness than centrifugal options, gear pumps have their own limitations:

- Metal-on-metal contact creates wear points

- Tight tolerances make them susceptible to abrasive particles

- Limited ability to handle entrained air

- Difficulty managing varying viscosities

Pneumatic Diaphragm Pumps

Though versatile, standard diaphragm pumps often lack:

- Sufficient pressure capability for truly thick materials

- Efficient air consumption at higher pressures

- Steady, pulse-free flow needed for precise applications

- Effective self-priming ability with extremely viscous materials

Introducing Graco's Check-Mate Pumps: Engineered for Extreme Viscosity

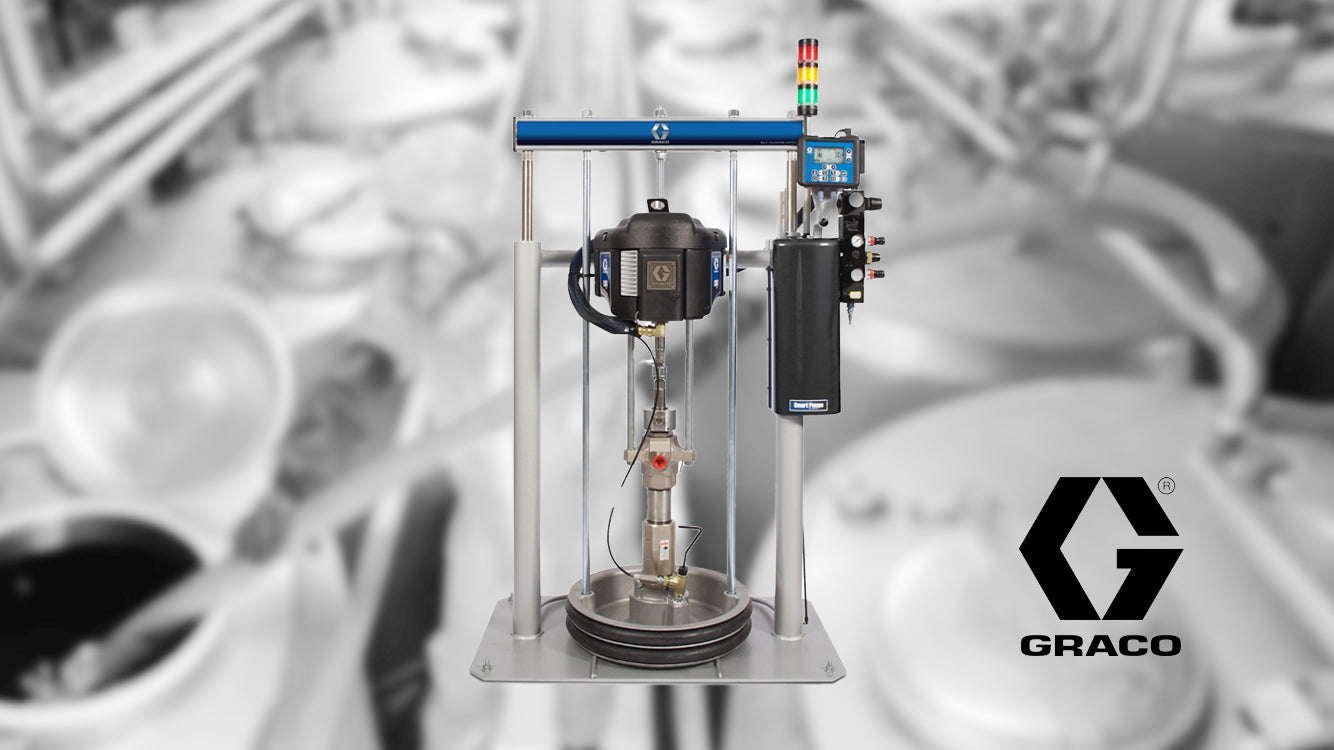

Graco's Check-Mate pumps represent a purpose-built solution for the toughest material transfer challenges. These high-pressure, high-volume displacement pumps operate on a fundamentally different principle than conventional technologies—one that excels specifically with high-viscosity materials.

Key Features That Make the Difference

1. Powerful Displacement Design

The Check-Mate's reciprocating piston design creates positive displacement that literally "pushes" material through the system rather than trying to "pull" it like many traditional pumps. This fundamental difference allows it to:

- Generate pressures up to 6,000 PSI (414 bar)

- Move materials with viscosities exceeding 1,000,000 cPs

- Maintain consistent output regardless of back pressure

2. Advanced Priming Capability

Check-Mate pumps feature:

- Large intake valves that facilitate material flow into the pump chamber

- Long stroke design that creates sufficient vacuum for self-priming

- Priming piston configurations for especially challenging materials

3. Superior Sealing Technology

Handling high-viscosity chemicals demands exceptional sealing, which Check-Mate delivers through:

- Long-lasting throat packings designed for abrasive materials

- Adjustable packing tension for optimal sealing and longevity

- Quick-replacement cartridge designs that minimize maintenance downtime

4. Versatile Material Compatibility

Chemical compatibility concerns are addressed through multiple construction options:

- Stainless steel fluid sections for corrosive environments

- Carbon steel versions for non-corrosive applications

- Various seal material options including PTFE, UHMWPE, and specialty elastomers

The Benefits: Measurable Advantages Over Traditional Methods

Implementing Graco Check-Mate pumps in your chemical manufacturing process delivers several quantifiable benefits:

1. Near-Complete Material Evacuation

Check-Mate pumps can recover up to 99% of material from containers, compared to the 85-90% typical with traditional methods. For expensive specialty chemicals or adhesives, this difference translates directly to thousands in saved material costs annually.

2. Reduced Labor and Maintenance Costs

The robust design requires less frequent maintenance than gear pumps or progressive cavity pumps, with:

- Easily serviceable wet cups that extend seal life

- Quick-disconnect lower pumps for fast service

- Fewer moving parts than complex alternative systems

3. Consistent Material Properties

Unlike high-shear pump designs that can alter material characteristics, Check-Mate pumps maintain chemical integrity through:

- Low-shear material transfer

- Minimal heat generation

- Gentle handling of shear-sensitive formulations

4. Improved Production Efficiency

Manufacturing operations benefit from:

- Faster material transfer rates

- Reduced downtime for drum or tote changes

- Consistent supply pressure for downstream processes

- Ability to pump directly from original shipping containers

Applications in Chemical Manufacturing

Check-Mate pumps excel in numerous chemical manufacturing scenarios:

- Adhesive Production: Transferring base polymers and finished adhesives with viscosities exceeding 500,000 cPs

- Sealant Manufacturing: Moving high-solids silicones and polyurethanes without separation

- Resin Systems: Handling epoxies and other reactive components with consistent proportions

- Lubricant Production: Transferring heavy greases and specialty lubricants

- Specialized Coatings: Moving high-solids content protective coatings while maintaining formulation integrity

Integration With Complete Material Handling Systems

Graco's Check-Mate pumps don't operate in isolation—they form the heart of comprehensive material handling systems that can include:

- Ram packages for following plates to prevent material cavitation

- Heated pressure plates for temperature-sensitive materials

- Automated controls for precise pressure and flow management

- Level sensors for seamless container changeover

- Multiple-pump configurations for large-volume applications

Why Partner With HMFT for Your Graco Solutions

As Canada's trusted distributor of Graco industrial equipment, HMFT brings specialized expertise to help chemical manufacturers implement optimal viscous material handling solutions:

- System design consultation based on your specific material properties

- Comprehensive equipment specification and sizing

- Installation support and commissioning assistance

- Operator training and maintenance guidance

- Ongoing technical support and service

Our deep understanding of both chemical manufacturing processes and Graco's equipment capabilities ensures you receive a solution perfectly tailored to your production requirements.

Conclusion: Transform Your High-Viscosity Material Handling

In today's competitive chemical manufacturing landscape, inefficient material handling processes directly impact profitability. By upgrading to Graco's Check-Mate pumps, you can overcome the limitations of traditional transfer methods, reduce waste, improve consistency, and ultimately enhance your bottom line.

Ready to revolutionize how you handle high-viscosity chemicals? Contact HMFT today for a personalized consultation on implementing Graco Check-Mate solutions in your facility. Let's transform your material handling challenges into a streamlined, efficient process that delivers measurable returns.

FAQ

Q: What viscosity range can Graco Check-Mate pumps handle?

A: Check-Mate pumps can effectively move materials from medium viscosities up to extremely thick materials exceeding 1,000,000 cPs—from the consistency of honey to materials that barely flow under their own weight.

Q: Do Check-Mate pumps require special installation considerations?

A: While they integrate with standard plant air systems, optimal performance often involves right-sizing air supply lines, selecting appropriate follower plate configurations, and system pressure calculations. Our HMFT engineers can assist with proper setup.

Q: How do Check-Mate pumps handle abrasive materials?

A: Their robust construction with hardened components and replaceable wear surfaces makes them ideal for abrasive materials. Various cylinder and seal materials can be selected based on the specific abrasive properties of your chemicals.

Q: Can these pumps be used in hazardous environments?

A: Yes, Check-Mate pumps are available with appropriate certifications for hazardous locations, including options that comply with ATEX standards for explosive atmospheres common in chemical manufacturing.

Q: What maintenance is required for Graco Check-Mate pumps?

A: Maintenance requirements are minimal compared to alternatives, typically involving periodic seal inspection and lubrication of the air motor. The serviceable design allows for quick wet-end maintenance without complete system removal.