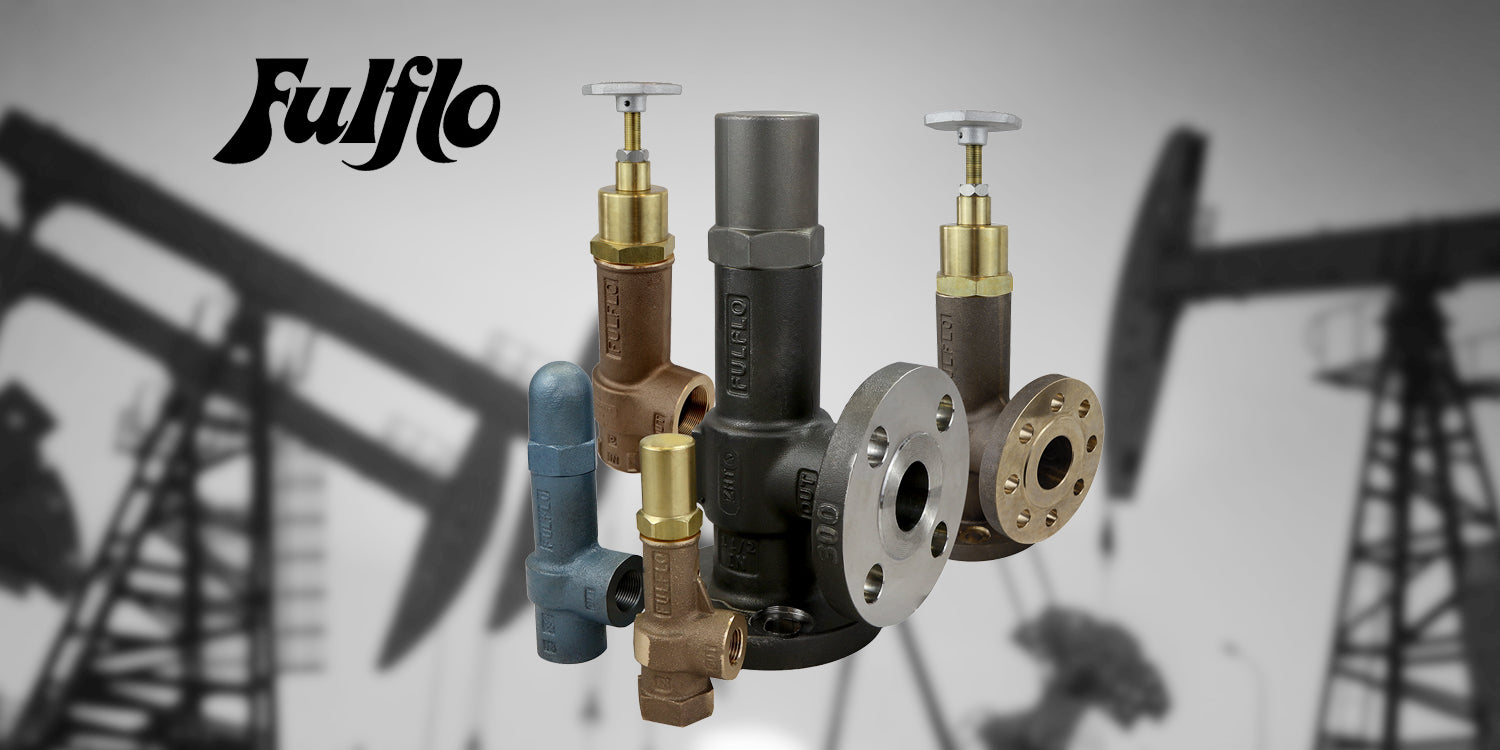

In the oil and gas industry, where operations demand precision, reliability, and adaptability, equipment must perform flawlessly under challenging conditions. Fulflo valves have become a trusted solution for fluid control in this sector, offering unmatched versatility and efficiency. Whether you're handling hydraulic oils, water, solvents, or chemicals, Fulflo valves are engineered to meet the diverse needs of oil and gas applications. In this blog, I’ll explore how these valves excel in various scenarios and why they’re a must-have for your operations.

Why Versatility Matters in Oil and Gas Operations

The oil and gas industry operates across a wide range of environments—offshore rigs, refining facilities, and upstream production sites. Each setting presents unique challenges, from managing fluids with varying viscosities to handling extreme pressures. Equipment that can adapt to these conditions is essential to maintain uptime and ensure safety.

Fulflo valves are designed with this versatility in mind. They operate efficiently with liquids of any viscosity at pressures ranging from 2 PSI to 1000 PSI. This broad operating range makes them suitable for countless applications within the industry.

Key Features That Set Fulflo Valves Apart

1. Compatibility with Various Fluids

One of the standout features of Fulflo valves is their ability to handle a wide range of liquids. From hydraulic oils to water, solvents, and chemicals, these valves maintain consistent performance regardless of fluid type or viscosity. This adaptability ensures that Fulflo valves can be seamlessly integrated into diverse oil and gas processes.

2. Wide Pressure Range

Fulflo valves are engineered to operate reliably at pressures as low as 2 PSI and as high as 1000 PSI. This flexibility allows them to function effectively in both low-pressure lubrication systems and high-pressure control applications. For example:

- In upstream operations, they can regulate flow in hydraulic fracturing systems.

- In downstream refining, they manage pressure in critical lubrication circuits.

3. Unique Sliding Piston Design

The sliding piston concept used in Fulflo valves minimizes chatter and ensures smooth operation even under fluctuating pressure conditions. Unlike conventional relief valves that may pound or squeal during transient surges, Fulflo guided piston valves remain stable and quiet.

4. Material Options for Harsh Environments

Fulflo valves are available in materials like brass, cast iron, steel, and stainless steel to withstand corrosive or abrasive conditions often encountered in oilfield environments. For instance:

- Stainless steel options are ideal for offshore platforms exposed to saltwater corrosion.

- Cast iron variants provide durability for onshore refining facilities handling heavy crude.

Applications of Fulflo Valves in Oil & Gas

1. Refining Processes

In refineries, where precise pressure control is critical to avoid equipment damage or process disruptions, Fulflo valves excel by maintaining consistent flow rates even under variable conditions. Their ability to handle high-viscosity fluids makes them ideal for heavy oil processing.

2. Pump and System Protection

Fulflo valves play a crucial role in safeguarding pumps and hydraulic systems from overpressure conditions. By acting as reliable bypass relief valves, they prevent costly equipment failures that could lead to unplanned downtime.

3. Offshore Drilling Operations

Offshore environments demand robust equipment capable of withstanding extreme temperatures, high pressures, and corrosive elements. Fulflo’s stainless steel models are particularly suited for these conditions, ensuring reliable operation on rigs and platforms.

4. Chemical Injection Systems

Chemical injection is a vital process in oilfield operations for preventing corrosion or scaling within pipelines. Fulflo valves ensure precise flow control of chemicals into the system while maintaining stable pressure levels.

Advantages Over Conventional Relief Valves

| Feature | Conventional Relief Valves | Fulflo Valves |

|---|---|---|

| Response to Pressure Surges | Prone to chatter or pounding | Stable operation without chatter |

| Fluid Compatibility | Limited | Handles all viscosities |

| Maintenance Requirements | Frequent adjustments needed | Minimal maintenance required |

This combination of superior performance and reduced maintenance needs makes Fulflo valves a cost-effective choice for long-term use in demanding oilfield environments.

Maximizing Efficiency with Fulflo Valves

Efficiency is a top priority in oil and gas operations where every second counts—and every dollar saved matters. By minimizing system power loss through optimized flow design, Fulflo valves ensure more energy is directed towards productive operations rather than being wasted within hydraulic systems.

For example: In a lubrication skid application, using a Fulflo valve can reduce energy consumption by maintaining optimal fluid flow without unnecessary pressure drops.

Conclusion: Why Choose Fulflo Valves?

Fulflo valves offer unparalleled versatility for the oil and gas industry by adapting seamlessly to various fluids, pressures, and operational demands. Their robust construction ensures durability in harsh environments while their innovative design minimizes downtime and maintenance costs.

At HMFT, we specialize in providing high-quality fluid-handling solutions tailored to your specific needs. Whether you’re looking to enhance system reliability or improve operational efficiency, our team is here to help you integrate Fulflo valves into your processes.

Ready to take your operations to the next level? Contact HMFT today for expert advice on selecting the right Fulflo valve for your application!

FAQs

What types of fluids can Fulflo valves handle? Fulflo valves are compatible with hydraulic oils, water, solvents, chemicals, and other liquids across a full range of viscosities.

What is the pressure range for Fulflo valves? They operate efficiently at pressures ranging from 2 PSI to 1000 PSI.

Are Fulflo valves suitable for corrosive environments? Yes! With material options like stainless steel and brass, they’re built to withstand corrosive conditions commonly found in offshore or refining applications.

How do Fulflo valves minimize system power loss? Their unique design reduces velocities through all but the controlling interface of the valve, ensuring efficient energy use within hydraulic systems.

What makes Fulflo valves better than conventional relief valves? Fulflo’s guided piston design eliminates chatter during transient pressure surges while offering compatibility with diverse fluids—features not typically found in conventional designs.