In the demanding world of power generation, reliability is paramount. Every component in a power plant must operate flawlessly to ensure continuous electricity production. Among these critical components are hydraulic systems, which play a vital role in various operations. At the heart of many of these systems are Fulflo valves, renowned for their ability to provide consistent, reliable performance in challenging environments.

The Fulflo Advantage

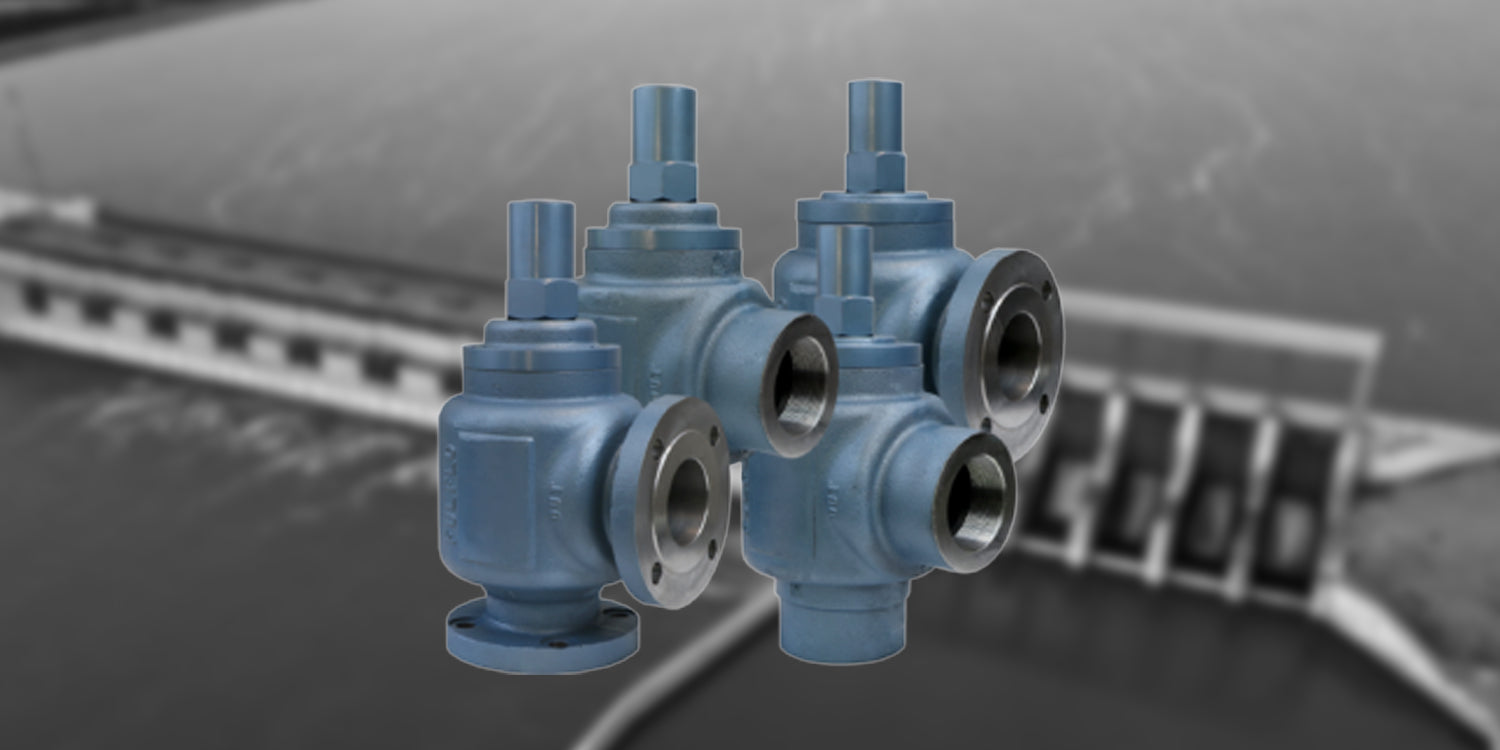

Fulflo valves have been pioneering hydraulic bypass relief valves since 1912, setting the standard for reliability in power plant operations. These valves are designed with a unique sliding piston concept and internal contours that offer exceptional flow and stability characteristics. This design ensures reliable performance without the chatter often associated with conventional valves.

Wide Operating Range

One of the key strengths of Fulflo valves is their versatility. They are engineered to operate reliably at pressures ranging from as low as 2 PSI to as high as 1000 PSI. This wide operating range makes them suitable for various applications within power plant hydraulic systems, from low-pressure lubrication circuits to high-pressure control systems.

Minimizing System Power Loss

In power generation, efficiency is crucial. Fulflo valves contribute to overall system efficiency by reducing velocities through all but the controlling interface of the valve. This design feature minimizes system power loss, ensuring that more energy is available for power generation rather than being wasted in the hydraulic system.

Stability in Demanding Conditions

Power plant environments can be challenging, with fluctuating pressures and temperatures. Fulflo guided piston valves are less responsive to transient pressure surges compared to ordinary direct-acting relief valves. This characteristic eliminates the tendency to pound, squeal, or chatter, ensuring quiet, stable, and efficient performance in both load regulation and system protection applications.

Versatility with Various Fluids

Power plants often use different types of hydraulic fluids depending on the specific application. Fulflo valves are designed to operate effectively with all types of liquids across a full range of viscosities, including hydraulic oils, water, solvents, and chemicals. This versatility makes them an ideal choice for diverse power plant applications.

Enhancing System Reliability

The reliability of any hydraulic system is improved when particle, heat, and water contamination are controlled. Fulflo valves, with their robust design and ability to handle various fluids, play a crucial role in maintaining system cleanliness and stability. When combined with proper maintenance practices, such as regular oil analysis and filtration, these valves can significantly enhance the overall reliability of power plant hydraulic systems.

Conclusion

In the high-stakes environment of power generation, the choice of components can make a significant difference in operational reliability and efficiency. Fulflo valves, with their proven track record and innovative design, offer power plants a solution that ensures consistent performance, reduces maintenance needs, and contributes to overall system efficiency.

By incorporating Fulflo valves into their hydraulic systems, power plants can take a significant step towards improving reliability, reducing downtime, and optimizing their operations. As the power generation industry continues to evolve, the role of reliable, efficient components like Fulflo valves will only become more critical in ensuring a stable and sustainable energy future.

For power plant operators looking to enhance their hydraulic system performance, considering Fulflo valves is a wise decision that can pay dividends in reliability and efficiency for years to come.

At HMFT, we understand the critical role that reliable hydraulic systems play in power generation. Our team of factory-trained technicians is available to service and repair Fulflo valves, ensuring they continue to operate at peak efficiency throughout their lifespan. Contact HMFT today to learn more about how we can support your power plant's hydraulic system needs and help you maintain optimal performance.

FAQs

Q: What pressure range can Fulflo valves handle?

A: Fulflo valves are designed to operate reliably at pressures ranging from 2 PSI to 1000 PSI.

Q: Can Fulflo valves work with different types of hydraulic fluids?

A: Yes, Fulflo valves operate effectively with various liquids, including hydraulic oils, water, solvents, and chemicals.

Q: How do Fulflo valves contribute to system efficiency?

A: Fulflo valves minimize system power loss by reducing velocities through all but the controlling interface of the valve.

Q: Are Fulflo valves suitable for high-temperature environments in power plants?

A: While specific temperature ratings should be checked, Fulflo valves are designed for demanding environments typical in power generation facilities.

Q: How do Fulflo valves compare to conventional relief valves?

A: Fulflo valves are less responsive to transient pressure surges, eliminating issues like pounding, squealing, or chattering often seen in conventional valves.

Q: What maintenance is required for Fulflo valves in power plant applications?

A: While Fulflo valves are designed for reliability, regular system checks, oil analysis, and proper filtration are recommended to ensure optimal performance.