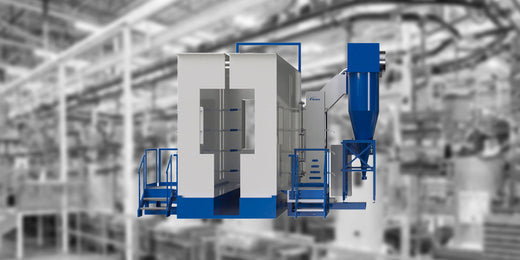

In today's fast-paced manufacturing world, efficiency is key. The Nordson ColorMax®2 Powder Coating Booth is revolutionizing the industry with its ability to perform rapid, contamination-free colour changes, significantly boosting productivity and flexibility for businesses of all sizes.

The ColorMax®2 Advantage

The ColorMax®2 system is designed with one primary goal: to minimize downtime and maximize output. Its innovative features work in harmony to achieve fast colour changes without compromising on quality or efficiency.

Rapid Color Change Technology

At the heart of the ColorMax®2 is its ability to perform colour changes in under 10 minutes. This remarkable speed is achieved through several key design elements:

- Minimized Powder in Process: The system is engineered to reduce the amount of powder in use at any given time, making colour transitions quicker and cleaner.

- Non-Conductive Booth Materials: The use of patented Apogee® composite material for the booth canopy minimizes powder attraction and retention, simplifying the cleaning process.

- Twin Cyclone Design: Uniquely designed, easy-to-clean steel twin cyclones facilitate complete cleaning of all surfaces, with hinged sections that pivot open for easy access.

Optimized Powder Recovery and Recycling

The ColorMax®2 doesn't just change colours quickly; it also ensures efficient use of materials:

- Prodigy® HDLV Transfer Pump: This technology enhances powder recovery and recycling, ensuring efficient cyclone performance and reduced wastage.

- Continuous Evacuation: The system continuously removes powder from the twin cyclone, maximizing efficiency and minimizing powder in process.

Flexibility to Meet Diverse Needs

Understanding that different industries have varying requirements, Nordson offers the ColorMax®2 in three models:

- Cubed

- Engineered

- Hybrid

Each model is tailored to specific operational needs, whether it's high-volume production or managing a diverse colour range.

Advanced Features for Superior Performance

The ColorMax®2 is packed with cutting-edge features that contribute to its exceptional performance:

- AeroWash™ Base Cleaning System: Ensures minimal powder build-up.

- AeroDeck™ Air Distribution System: Maintains booth cleanliness and facilitates faster colour changes.

- iControl® 2 Integrated Control System: Provides precise control over application parameters, guaranteeing consistent output quality.

- Encore® Automatic Guns: Cleaned automatically, reducing manual labor and potential contamination.

The Impact on Productivity

By implementing the ColorMax®2 system, businesses can expect:

- Reduced Downtime: Faster colour changes mean less time spent on non-productive tasks.

- Increased Flexibility: The ability to handle both short and long runs efficiently.

- Improved Material Efficiency: Enhanced powder recovery and recycling lead to less waste.

- Consistent Quality: Precise control and contamination-free changes ensure high-quality finishes every time.

Conclusion

The Nordson ColorMax®2 Powder Coating Booth represents a significant leap forward in coating technology. Its ability to perform rapid, clean colour changes, coupled with its flexible design and advanced features, makes it an invaluable asset for any powder coating operation looking to boost productivity and stay competitive in today's fast-paced manufacturing environment.

By investing in the ColorMax®2, businesses are not just purchasing equipment; they're investing in efficiency, quality, and the future of their coating operations. As the manufacturing world continues to evolve, tools like the ColorMax®2 will be essential in meeting the demands of tomorrow's market.