As distributors of Roper pumps in Canada, we at HMFT have seen firsthand how crucial it is to have reliable, safe, and efficient pumping solutions when handling hazardous chemicals. In the chemical manufacturing industry, where the stakes are high and the risks are real, Roper's sealed pump technology stands out as a game-changer. Let us walk you through why Roper pumps are the go-to choice for many chemical manufacturers.

The Challenge of Handling Hazardous Chemicals

In chemical manufacturing, we're often dealing with substances that are corrosive, toxic, or volatile. The risks associated with these materials are significant:

- Environmental contamination from leaks

- Health hazards for workers

- Potential for fires or explosions

- Loss of valuable product

- Compliance issues with strict regulations

That's why having the right pumping technology isn't just about efficiency—it's about safety, compliance, and protecting your bottom line.

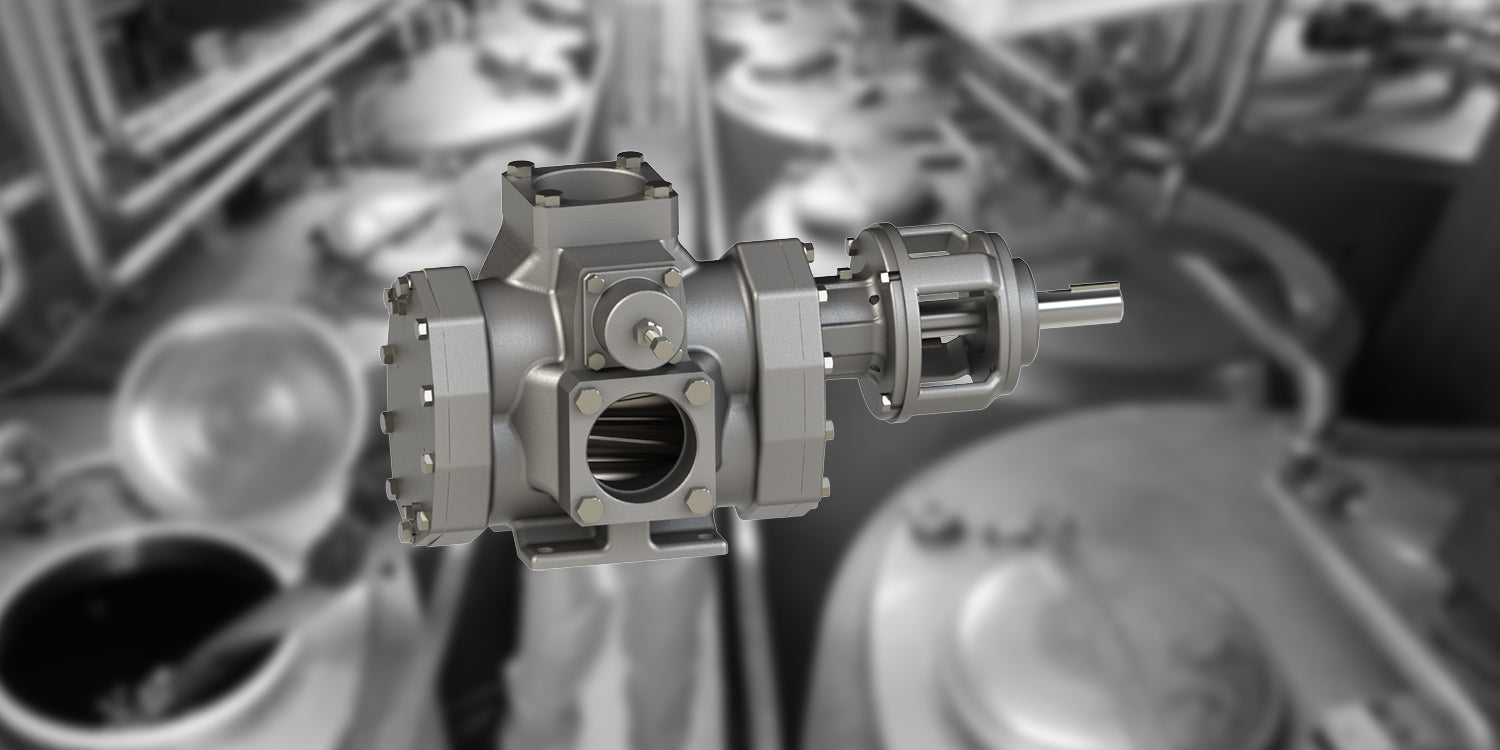

Roper's Sealed Pump Technology: A Closer Look

Roper has been at the forefront of pump technology since 1857, and their sealed pump designs are a testament to their commitment to safety and efficiency. Here's what makes Roper's sealed pumps stand out:

1. Advanced Sealing Mechanisms

Roper offers a variety of sealing options to suit different applications:

- Mechanical Seals: These provide excellent containment for a wide range of chemicals.

- Triple Lip Seals: Designed for applications where zero leakage is critical.

- Cartridge Seals: Offer easy installation and maintenance, ideal for harsh environments.

2. Robust Construction

Roper pumps are built to last, with materials chosen for their durability and chemical resistance:

- Ductile iron housings

- Hardened steel shafts and gears

- Stainless steel options for highly corrosive applications

3. Safety Features

Safety is paramount in Roper's design philosophy:

- Built-in relief valves to prevent over-pressurization

- Bi-directional pressure relief for added protection

- Sealless magnetic drive options for ultimate containment

The Benefits for Chemical Manufacturers

By choosing Roper's sealed pump technology, chemical manufacturers can expect:

- Enhanced Safety: The advanced sealing mechanisms significantly reduce the risk of leaks and spills, protecting workers and the environment.

- Improved Efficiency: Precise manufacturing tolerances and optimized designs ensure maximum pumping efficiency, reducing energy costs.

- Reduced Maintenance: The robust construction and high-quality seals mean less downtime and lower maintenance costs over the pump's lifetime.

- Versatility: Roper offers a wide range of pump sizes and configurations to suit various chemical applications, from viscous liquids to corrosive substances.

- Compliance: By minimizing the risk of leaks and emissions, Roper pumps help manufacturers stay compliant with stringent environmental regulations.

Conclusion: Investing in Safety and Efficiency

In the world of chemical manufacturing, cutting corners on pump technology is never an option. Roper's sealed pump technology offers the perfect blend of safety, efficiency, and reliability that modern chemical manufacturers need.

As your Canadian distributor for Roper pumps, we at HMFT are committed to helping you find the right pumping solution for your specific needs. Whether you're dealing with corrosive chemicals, high-viscosity fluids, or need precise metering, there's a Roper pump designed to meet your challenges head-on.

Investing in Roper's sealed pump technology isn't just about buying a pump—it's about investing in the safety of your workers, the protection of the environment, and the efficiency of your operations. In an industry where the stakes are high, Roper pumps provide the peace of mind you need to focus on what you do best: producing high-quality chemicals safely and efficiently.

Ready to upgrade your pumping systems with Roper's cutting-edge technology? Let's talk about how we can tailor a solution for your specific chemical manufacturing needs.

FAQs

Q: Are Roper pumps suitable for handling a wide range of chemicals?

A: Yes, Roper offers pumps in various materials and configurations to handle diverse chemicals, from acids to solvents.

Q: How do Roper's sealed pumps compare to sealless options in terms of safety?

A: While both offer excellent safety, sealed pumps can be more cost-effective for certain applications while still providing high levels of containment.

Q: What maintenance is required for Roper's sealed pumps?

A: Maintenance needs are minimal, but regular inspections and occasional seal replacements are recommended to ensure optimal performance.

Q: Can Roper pumps handle high-viscosity fluids?

A: Absolutely. Many Roper pump models are specifically designed to handle viscous fluids efficiently.

Q: How does Roper ensure the reliability of their pumps in harsh chemical environments?

A: Roper uses high-quality, corrosion-resistant materials and advanced sealing technologies to ensure reliability in even the most challenging chemical applications.