Automotive manufacturing is an industry that demands precision, efficiency, and reliability at every turn. From adhesive application to sealant dispensing, the equipment used must be tough enough to handle high-viscosity materials, rigorous production schedules, and challenging industrial environments. That’s where Graco Check-Mate pumps shine.

Designed with durability and performance in mind, Graco Check-Mate pumps are built to withstand the harsh realities of automotive assembly plants while delivering consistent results. In this blog, we’ll explore why these pumps are the ultimate choice for manufacturers looking to optimize their operations and minimize downtime.

The Unique Challenges of Automotive Manufacturing

Automotive assembly plants operate under intense pressure to meet production quotas without compromising quality. This means every piece of equipment must perform flawlessly under demanding conditions. Here are some of the challenges faced by fluid handling systems in these environments:

- High-Viscosity Materials: Adhesives, sealants, and lubricants used in automotive manufacturing often have thick consistencies that require robust pumps capable of handling them without clogging or slowing down.

- Continuous Operation: Production lines run for extended hours, requiring equipment that can operate reliably without frequent maintenance or breakdowns.

- Harsh Environments: Industrial settings expose pumps to dust, debris, temperature fluctuations, and chemical exposure—all of which can wear down components over time.

- Precision Requirements: Fluid application must be accurate to ensure consistent bonding, sealing, or lubrication without waste or defects.

Graco Check-Mate pumps are specifically engineered to tackle these challenges head-on, making them a trusted choice for automotive manufacturers worldwide.

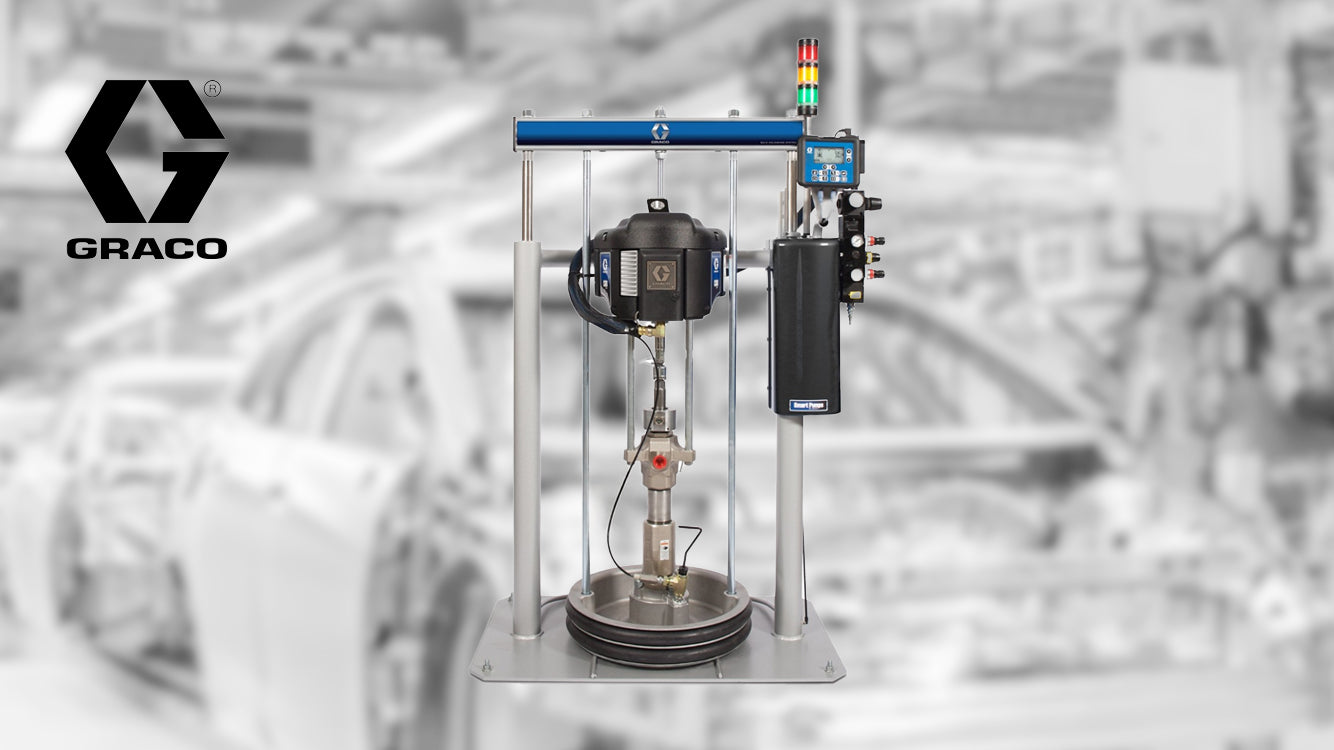

What Makes Graco Check-Mate Pumps So Durable?

The durability of Graco Check-Mate pumps is no accident—it’s the result of thoughtful design and high-quality materials that ensure reliable performance even in the toughest conditions. Let’s take a closer look at what sets these pumps apart:

1. Robust Construction

Graco Check-Mate pumps are built with heavy-duty components designed to withstand wear and tear. From stainless steel wetted parts to hardened seals and pistons, every element is crafted for long-term durability. This rugged construction ensures the pump can handle abrasive materials like epoxies and urethanes without compromising performance.

2. Floating Piston Seals

A standout feature of Check-Mate pumps is their floating piston seals. Unlike traditional seals that wear out quickly under constant use, floating seals adjust dynamically to maintain a secure fit. This reduces friction and extends the lifespan of the pump while ensuring consistent operation over time.

3. Severe Duty Options

For plants dealing with particularly challenging materials or environments, Graco offers Severe Duty versions of Check-Mate pumps. These models come equipped with enhanced components designed for maximum resistance to corrosion, abrasion, and extreme temperatures.

4. Enclosed Wet Cups

The enclosed wet cup design prevents contamination of seals by keeping them lubricated and protected from external debris. This not only improves durability but also reduces maintenance needs—a win-win for busy production lines.

5. High Pressure Capabilities

Check-Mate pumps can handle pressures up to 5,000 psi (345 bar), making them ideal for high-viscosity materials that require significant force for proper dispensing. This capability ensures consistent application even under demanding conditions.

Applications in Automotive Assembly Plants

The versatility of Graco Check-Mate pumps makes them indispensable across various processes in automotive manufacturing:

Adhesive Dispensing

From bonding body panels to attaching trim pieces, adhesives play a critical role in vehicle assembly. Check-Mate pumps deliver precise application of adhesives with minimal bead distortion or waste, ensuring strong bonds and clean finishes.

Sealant Application

Sealants are essential for waterproofing and vibration dampening in vehicles. Whether it’s glass glazing or seam sealing, Check-Mate pumps provide consistent flow rates for uniform coverage without gaps or overspray.

Lubrication Systems

Machinery used in automotive plants requires regular lubrication to prevent wear and ensure smooth operation. Check-Mate pumps efficiently handle grease and oils even at high viscosities, keeping equipment running reliably.

Bulk Material Transfer

Check-Mate pumps excel at transferring materials from drums or bulk containers to dispensing stations. Their ability to handle large volumes quickly and efficiently supports high-volume production lines without delays.

The ROI of Investing in Durability

While durable equipment like Graco Check-Mate pumps may come with a higher upfront cost compared to less robust alternatives, the long-term benefits far outweigh the investment:

- Reduced Downtime: Reliable performance minimizes interruptions caused by equipment failure or repairs.

- Lower Maintenance Costs: Long-lasting components mean fewer replacements and less frequent servicing.

- Improved Productivity: Consistent operation ensures production lines run smoothly without bottlenecks or delays.

- Sustainability Benefits: Efficient material usage reduces waste while extending equipment life aligns with eco-friendly practices.

The HMFT Advantage: Supporting Canadian Automotive Manufacturers

If you’re looking for durable fluid handling solutions tailored to your needs, HMFT is here to help. As an authorized distributor of Graco products in Canada, we provide expert consultation, installation support, training services, and access to replacement parts—all backed by our commitment to excellence.

No matter your challenge—whether it’s handling high-viscosity materials or reducing downtime—we’ll work with you to find the perfect solution using Graco Check-Mate pumps.

Conclusion

The demands of automotive manufacturing require equipment that can keep up—and Graco Check-Mate pumps deliver on every front. With their robust construction, innovative features, and proven reliability under pressure, these pumps are built to last while improving efficiency across your operations.

If you’re ready to upgrade your fluid handling systems with durable solutions that stand the test of time, contact HMFT today! Let us help you implement Graco Check-Mate technology in your facility so you can focus on what matters most: building exceptional vehicles efficiently and reliably.

FAQ

1. What types of materials can Graco Check-Mate pumps handle?

Check-Mate pumps are designed for medium- to high-viscosity materials such as adhesives, sealants, lubricants, epoxies, urethanes, greases, and more.

2. Are these pumps suitable for high-pressure applications?

Yes! Check-Mate pumps can handle pressures up to 5,000 psi (345 bar), making them ideal for demanding applications like adhesive dispensing or bulk material transfer.

3. How do floating piston seals improve durability?

The floating piston seals adjust dynamically during operation to reduce friction and wear on components while maintaining a secure fit—extending pump lifespan significantly.

4. Can I use Severe Duty models for extreme environments?

Absolutely! Severe Duty versions are equipped with enhanced components designed specifically for harsh conditions such as extreme temperatures or abrasive materials.

5. Does HMFT provide installation support?

Yes! As an authorized distributor of Graco products in Canada, HMFT offers full installation guidance along with ongoing maintenance support to ensure peak performance from your equipment.