In the automotive refinish world, every detail matters. You can use the best paint, the most skilled technicians, and the latest spray guns, but if your paint booth is running on bargain filters, you’re risking more than you might think. At first glance, off-brand or low-cost filters seem like a smart way to save a few bucks. In reality, though, they can cost your shop far more in the long run—through rework, equipment damage, and lost productivity. Let’s break down why investing in high-quality, GFS-approved filters is one of the smartest decisions you can make for your shop.

The Hidden Dangers of Cheap Filters

It’s tempting to grab the least expensive filters on the market, especially when you’re watching your bottom line. But cheap filters are cheap for a reason. They’re often made with lower-grade materials, have inconsistent construction, and lack the rigorous testing that GFS-approved filters undergo. Here’s what that means for your shop:

- Lower Capture Efficiency: Bargain filters let more dust, dirt, and overspray escape into your booth and onto your fresh paint jobs. The result? More contamination, more rework, and more wasted materials.

- Frequent Changeouts: Inferior filters clog up faster, meaning you’ll be swapping them out more often. That’s more downtime and higher labour costs.

- Equipment Wear: When filters don’t do their job, overspray and particulates can build up on fans, ductwork, and heating elements. Over time, this leads to expensive repairs—or even premature replacement of critical booth components.

The True Cost: More Than Just the Price Tag

Let’s put it into perspective. Saving a few dollars per filter might look good on an invoice, but what about the hidden costs?

- Rework and Material Waste: Every contaminated paint job means sanding, repainting, and more materials down the drain.

- Downtime: Frequent filter changes and equipment repairs pull technicians away from productive work.

- Shortened Equipment Life: Fans and motors caked with overspray don’t last as long, leading to major replacement expenses.

- Customer Satisfaction: Nothing hurts your reputation like delivering a car with visible dust nibs or a finish that doesn’t meet your standards.

When you add it all up, those “savings” can quickly turn into a major drain on your profits.

Why GFS-Approved Filters Make the Difference

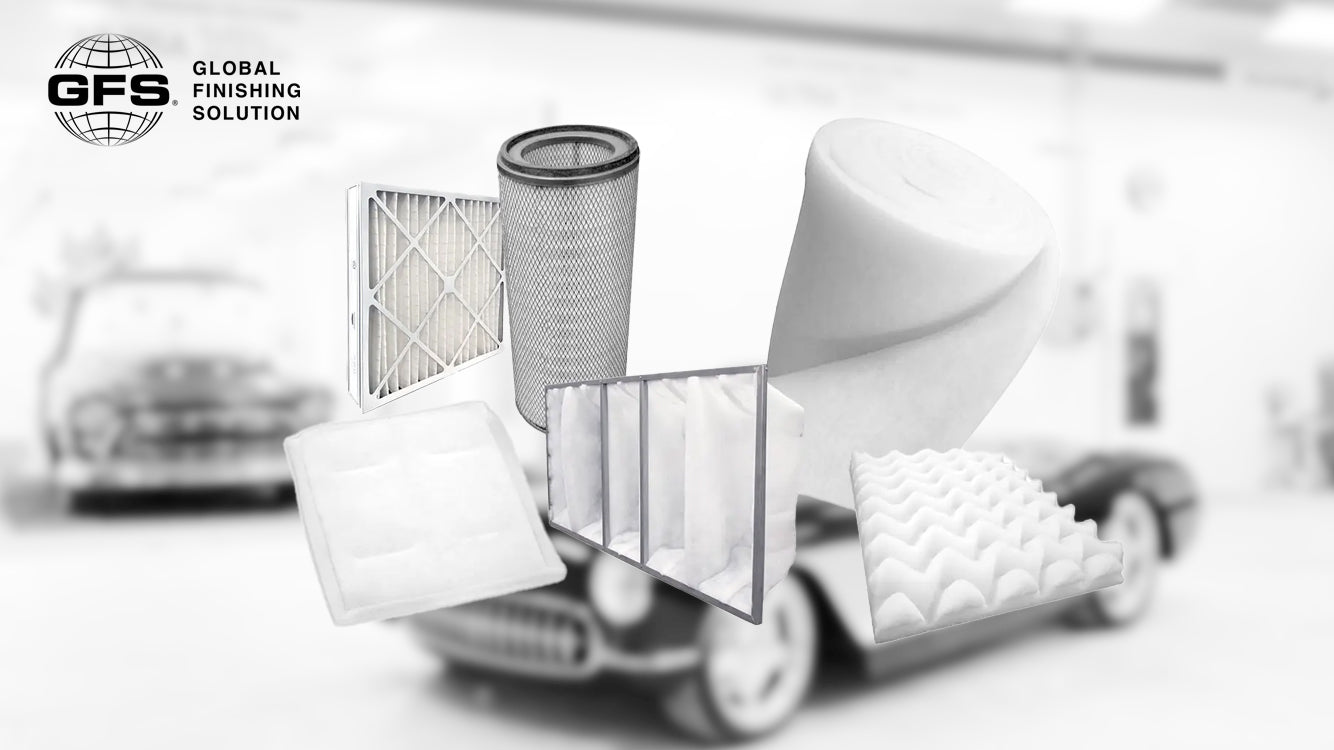

Global Finishing Solutions (GFS) doesn’t just build world-class paint booths—they engineer every component to work together for optimal performance. GFS-approved filters are designed specifically for your booth’s airflow and capture requirements, ensuring maximum efficiency and protection.

What sets GFS filters apart?

- Consistent Quality: Manufactured to strict standards for reliable performance every time.

- Optimal Fit: Designed to seal properly and prevent bypass, so all air is filtered as intended.

- Proven Capture Efficiency: Tested to trap even the finest particulates and overspray, protecting both your finishes and your equipment.

- Longer Service Life: Engineered to last longer between changes, reducing downtime and labour costs.

Protect Your Investment—and Your Reputation

Your paint booth is one of the biggest investments in your shop. Protecting it with the right filters is just good business sense. High-quality filtration keeps your booth running at peak efficiency, delivers cleaner finishes, and helps you avoid costly repairs. Most importantly, it ensures that every car leaving your shop looks its absolute best.

Conclusion

Cutting corners on filters might seem like a small thing, but it can have outsized consequences for your shop’s productivity, reputation, and bottom line. Don’t let cheap filters cost you more in the long run. Trust GFS-approved filters to keep your booth—and your business—running smoothly.

At HMFT, we’re committed to helping automotive refinish shops get the most out of their equipment. If you’re ready to upgrade your filtration and see the difference for yourself, reach out to our team today. Your finishes—and your customers—will thank you.

FAQ

Q: How often should I replace my paint booth filters?

A: It depends on your booth’s usage and the type of coatings you spray, but GFS recommends regular inspections and replacement as soon as filters show signs of loading or airflow restriction.

Q: Are GFS filters really different from generic filters?

A: Absolutely. GFS filters are engineered and tested for specific booth models, ensuring optimal fit, efficiency, and protection.

Q: What problems can cheap filters cause for my booth?

A: Low-quality filters can lead to more contamination, frequent changeouts, equipment wear, and even costly repairs or replacements.

Q: Can better filters really improve my paint finishes?

A: Yes! High-quality filters mean cleaner air in the booth, which translates to fewer defects and a superior finish on every job.

Q: How do I know which filter is right for my GFS booth?

A: HMFT’s team can help you select the correct GFS-approved filter for your booth model and workload. Just ask!