When it comes to wood processing, safety and efficiency are often two sides of the same coin. The industry is no stranger to risks, with combustible dust being one of the most significant hazards faced by sawmills, pulp and paper plants, and panel manufacturers. A single spark can ignite wood dust particles suspended in the air, leading to devastating explosions that can damage equipment, endanger workers, and halt production.

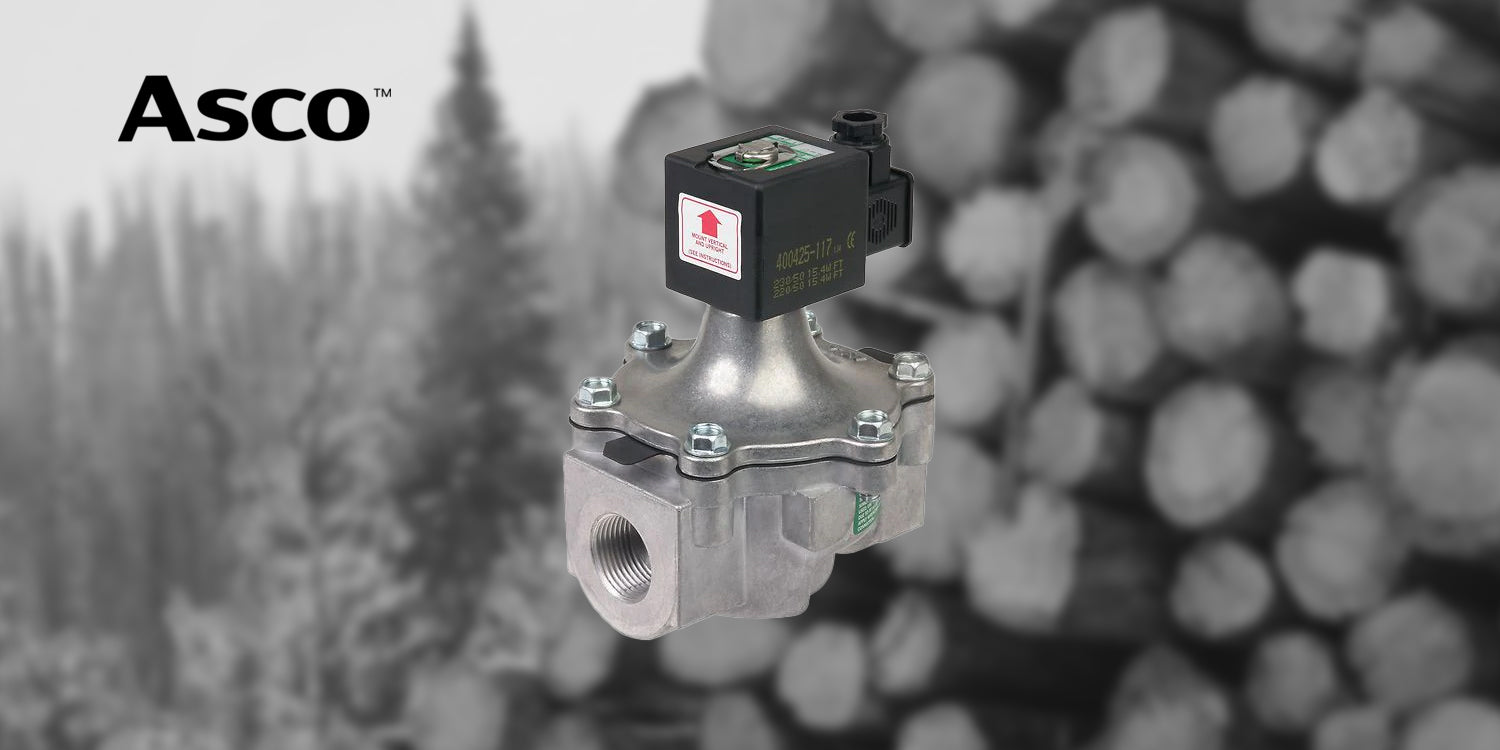

So, how do you mitigate this risk? One key solution lies in the use of explosion-proof solenoid valves like those offered by ASCO. These rugged, high-performance valves are designed to operate safely in hazardous environments, making them an essential component in your dust control and pneumatic systems.

Understanding the Risks of Combustible Dust in Wood Processing

Wood dust is a byproduct of nearly every stage of wood processing—from sawing and sanding to chipping and grinding. While it might seem harmless when settled on surfaces, airborne wood dust poses a serious threat.

Why is wood dust so dangerous?

- High Flammability: Wood particles can ignite at relatively low temperatures.

- Explosive Potential: When mixed with air in the right concentration, wood dust becomes highly combustible.

- Widespread Distribution: Dust can accumulate on machinery, ductwork, and other surfaces, increasing the risk of ignition.

Common ignition sources include overheated equipment, electrical sparks, and static discharge. Without proper safeguards in place, a small ignition source can trigger a chain reaction that results in catastrophic explosions.

How Explosion-Proof Solenoid Valves Protect Your Operations

Explosion-proof solenoid valves are engineered to prevent sparks or heat from escaping their enclosures and igniting flammable materials in the surrounding environment. In wood processing facilities, these valves play a critical role in controlling airflow, dust collection systems, and fire suppression systems.

Key Features of ASCO Explosion-Proof Solenoid Valves

- Certified for Hazardous Locations: ASCO valves meet stringent safety standards such as ATEX (Europe), CSA (Canada), and UL (United States), ensuring compliance with industry regulations for explosive atmospheres.

- Rugged Construction: Built with durable materials like stainless steel or aluminum housings to withstand harsh environments and resist corrosion from wood dust or moisture.

- Sealed Enclosures: Prevents internal components from coming into contact with external contaminants or flammable gases/dusts.

- Reliable Operation: Designed for long-term performance under high-pressure conditions common in pneumatic and hydraulic systems used in wood processing plants.

Applications of Explosion-Proof Solenoid Valves in Wood Processing

Explosion-proof solenoid valves are versatile and can be integrated into various systems across your facility:

1. Dust Collection Systems

Dust collection systems are your first line of defence against combustible dust hazards. Explosion-proof solenoid valves control the airflow within these systems, ensuring efficient dust removal from work areas while minimizing the risk of ignition inside ducts or filters.

2. Pneumatic Conveyors

Pneumatic conveyors are commonly used to transport wood chips, sawdust, and other materials throughout processing facilities. ASCO solenoid valves regulate the compressed air flow that powers these conveyors while maintaining safety in potentially explosive environments.

3. Fire Suppression Systems

In high-risk areas such as sanding lines or sawmills, fire suppression systems equipped with explosion-proof solenoid valves ensure rapid activation of water or foam deluge systems if a fire is detected.

4. Kiln Ventilation Controls

Drying kilns generate heat and release volatile organic compounds (VOCs) that can ignite under certain conditions. Explosion-proof solenoid valves help regulate ventilation systems to maintain safe operating conditions.

The Cost of Neglecting Combustible Dust Safety

Failing to address combustible dust hazards can have severe consequences:

- Operational Downtime: A single explosion can halt production for weeks or months while repairs are made.

- Financial Losses: Equipment damage and regulatory fines add up quickly.

- Worker Safety Risks: The health and safety of your employees should always be a top priority.

- Reputation Damage: Incidents can tarnish your company’s reputation within the industry.

Investing in explosion-proof solenoid valves is a proactive step toward mitigating these risks while ensuring compliance with safety standards.

Why Choose ASCO Explosion-Proof Solenoid Valves?

ASCO has been a trusted name in industrial automation for decades, offering solutions designed specifically for hazardous environments like those found in wood processing facilities.

Benefits of Choosing ASCO:

- Proven reliability backed by industry certifications

- Wide range of valve configurations to suit your specific needs

- Expert support from distributors like HMFT who understand your industry challenges

- Long-lasting performance, even under demanding conditions

Conclusion

Combustible dust is an ever-present danger in the wood processing industry—but it doesn’t have to be a ticking time bomb for your operation. By integrating explosion-proof solenoid valves into your critical systems, you’re taking a major step toward protecting both your equipment and your workforce from potential disasters.

At HMFT, we specialize in providing ASCO solutions tailored to the unique needs of forest product companies across Canada. Whether you’re looking to upgrade your dust collection system or enhance fire suppression capabilities, we’re here to help you find the right products for your operation.

Don’t wait until it’s too late—contact us today to learn more about how ASCO explosion-proof solenoid valves can safeguard your facility against combustible dust hazards.

FAQ

- Q: What makes a solenoid valve "explosion-proof"?

- A: Explosion-proof solenoid valves are designed with sealed enclosures that prevent internal sparks or heat from igniting flammable gases or dust in the surrounding environment.

- Q: Are explosion-proof valves mandatory for all wood processing facilities?

- A: While regulations vary by region, facilities handling combustible materials like wood dust are typically required to use explosion-proof equipment in hazardous areas.

- Q: How do I know if my facility needs explosion-proof solenoid valves?

- A: If your operation involves handling combustible dust or flammable gases, you likely need explosion-proof equipment to comply with safety standards such as ATEX or CSA.

- Q: Can ASCO explosion-proof solenoid valves handle high temperatures?

- A: Yes, many ASCO models are designed for high-temperature applications such as kiln ventilation or steam control systems.

- Q: How often should I inspect my explosion-proof solenoid valves?

- A: Regular inspections should be part of your maintenance schedule to ensure optimal performance and compliance with safety regulations. Frequency depends on operating conditions but should generally occur at least annually.