The Significance of Flow Control in Industrial Facilities

In the complex landscape of industrial facilities, one crucial element often overlooked is flow control. Efficiently managing the flow of liquids and gases is paramount for ensuring the smooth operation of various processes. From chemical plants to wastewater treatment facilities, the ability to precisely regulate flow rates can significantly impact productivity, safety, and overall costs.

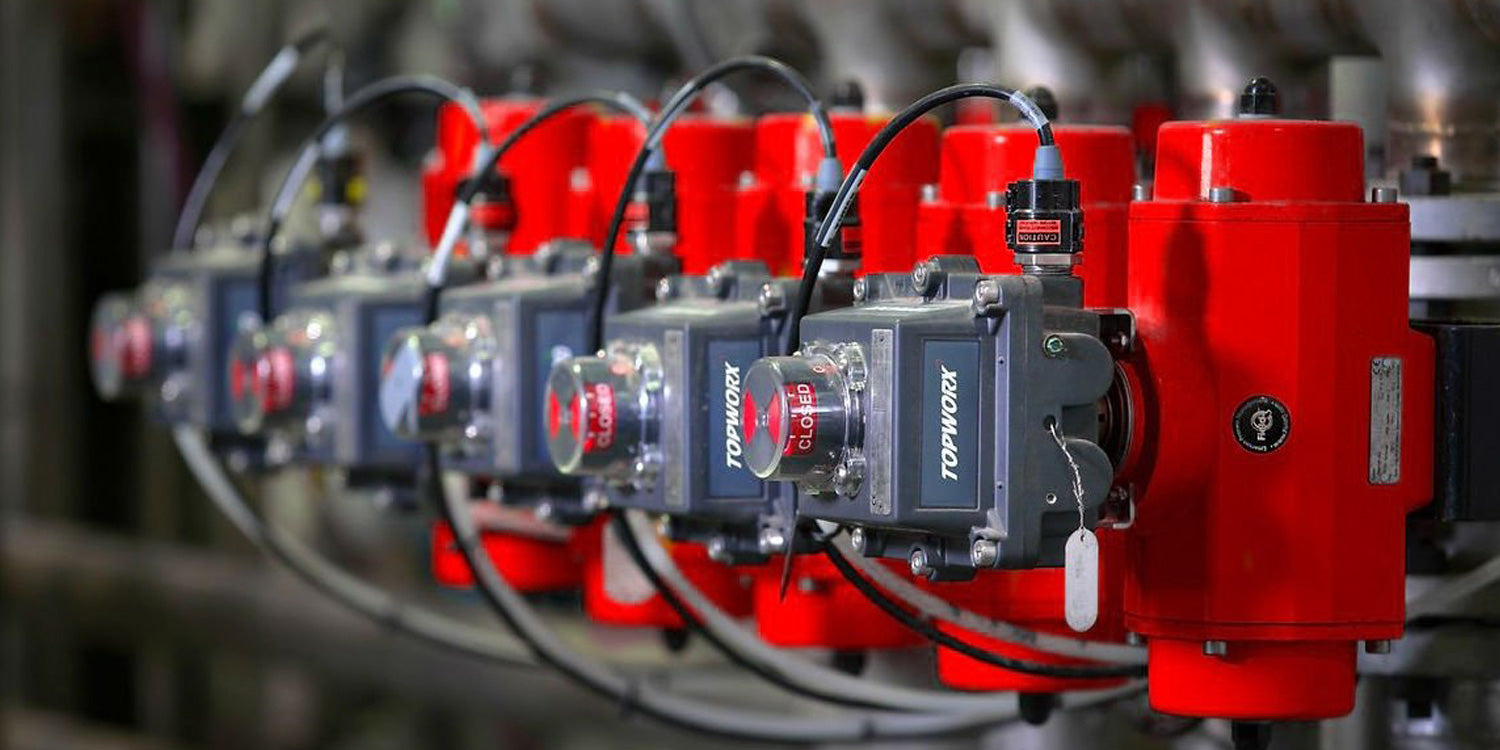

This is where Topworx Valve Positioners come into play. These precision instruments are engineered to optimize flow control with unmatched accuracy and reliability. If you're not already familiar with Topworx Valve Positioners, you're in for a treat. These devices have garnered a reputation in the industry for their exceptional performance.

Benefits of Using Topworx Valve Positioners

- Precision Control: Topworx Valve Positioners offer the ability to fine-tune valve positions, ensuring that flow rates are precisely controlled. This precision minimizes the risk of product wastage and improves product quality.

- Reliability: In industrial environments, reliability is paramount. Topworx Valve Positioners are known for their robust design, capable of withstanding harsh conditions and providing consistent performance over the long term.

- Cost-Effectiveness: Investing in Topworx Valve Positioners can lead to substantial cost savings. By optimizing flow control, you reduce energy consumption, extend the lifespan of equipment, and minimize maintenance costs.

Real-world Applications

Let's delve into real-world scenarios where Topworx Valve Positioners have made a significant impact:

- Chemical Industry: In chemical processing plants, precise control of chemicals' flow rates is vital for product quality and safety. Topworx Valve Positioners ensure that chemicals are dosed accurately, reducing the likelihood of costly spills or contamination.

- Oil and Gas: In the oil and gas industry, the transportation of liquids and gases through pipelines requires flawless control. Topworx Valve Positioners enhance efficiency, minimize leakage, and reduce downtime.

- Water Treatment: Wastewater treatment plants must manage vast volumes of water efficiently. Topworx Valve Positioners help optimize the flow of water, reducing energy consumption and operational costs.

The benefits of using Topworx Valve Positioners in industrial facilities are undeniable. Their precision, reliability, and cost-effectiveness make them a valuable addition to any operation aiming to optimize flow control. If you're seeking to enhance efficiency and reduce costs in your industrial facility, Topworx Valve Positioners should be at the top of your list. Discover how these remarkable instruments can transform your processes and help you achieve your efficiency goals.

At HMFT, we pride ourselves on more than just selling top-quality products. We boast a team of technical experts intimately familiar with the products we offer. Beyond that, our trained service technicians are equipped with the skills and experience to handle installation, repairs, and routine maintenance, ensuring our customers enjoy the full potential and longevity of their purchases. Your satisfaction, backed by our expertise, is our commitment.