In the fast-paced world of automotive manufacturing, precision and reliability are non-negotiable. Every component, from windshields to body panels, must be securely bonded and sealed to ensure structural integrity, durability, and aesthetic appeal. This is where Graco's advanced sealant and adhesive systems shine. With cutting-edge technology designed for accuracy and efficiency, Graco equipment is transforming how automakers approach bonding and sealing applications.

In this blog, we’ll explore how Graco’s sealant systems elevate automotive assembly processes, ensuring durability while reducing waste and costs.

Why Sealants and Adhesives Are Critical in Automotive Manufacturing

Sealants and adhesives play a pivotal role in modern vehicle assembly. They’re not just about holding things together—they’re about enhancing performance. Here’s why they matter:

- Structural Integrity: Adhesives distribute stress evenly across bonded surfaces, reducing the risk of failure.

- Weight Reduction: By replacing traditional mechanical fasteners like bolts and screws, adhesives help reduce vehicle weight, improving fuel efficiency.

- Vibration Dampening: Properly applied sealants minimize noise and vibrations for a quieter ride.

- Environmental Protection: Sealing applications prevent moisture, dust, and other contaminants from compromising vehicle components.

However, achieving these benefits requires precision in application—a challenge that Graco’s advanced systems are uniquely equipped to handle.

Graco’s Advanced Sealant Systems: Precision Meets Efficiency

Graco offers a range of innovative solutions for metering, mixing, and dispensing sealants and adhesives. These systems are engineered to meet the demands of automotive manufacturing with unparalleled accuracy.

1. Consistent Application for Superior Durability

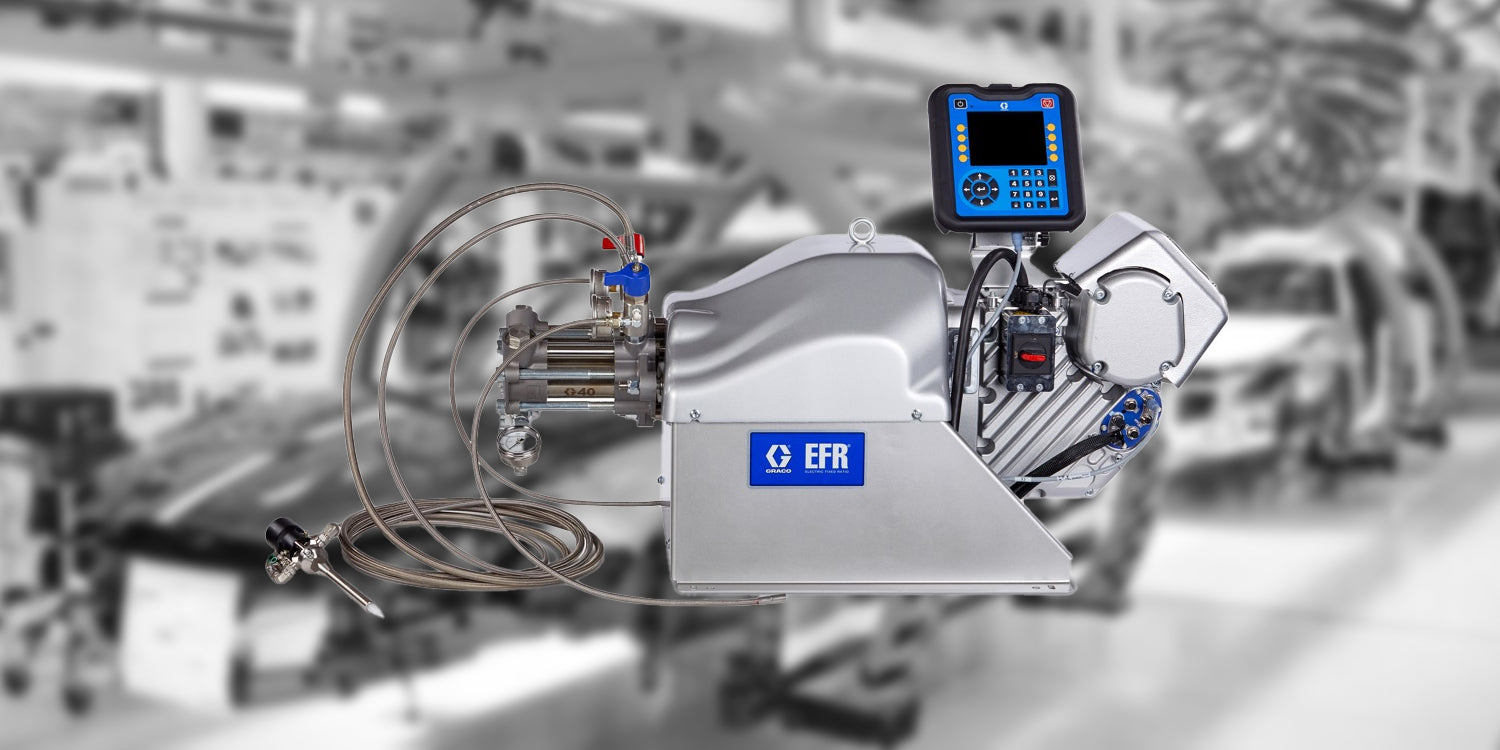

Graco’s Electric Fixed Ratio (EFR) system is a game-changer for two-component sealants and adhesives. It ensures precise on-ratio mixing and dispensing, eliminating guesswork. Whether you’re working with high-viscosity materials like urethanes or silicones, the EFR system delivers consistent beads or dots every time. This level of precision enhances durability by ensuring optimal bonding strength.

2. Reduced Waste for Cost Savings

Material waste is a significant concern in automotive assembly. Graco’s metering systems are designed to minimize waste by maintaining consistent material flow and pressure. For example:

- The ExactaBlend AGP system monitors and mixes components with unmatched accuracy, reducing scrapped parts.

- Advanced technologies like visual indicators confirm on-ratio dispensing, so you can trust the quality of every application.

These features not only improve profitability but also align with sustainability goals by reducing material consumption.

3. Modular Design for Easy Maintenance

One of the standout features of Graco systems is their modular design. Pumps can be rebuilt on-site, eliminating the need for costly external repairs or backup equipment. This design improves uptime and throughput—critical factors in high-volume automotive production lines.

Applications in Automotive Manufacturing

Graco’s sealant systems are versatile enough to handle a wide range of applications across the automotive assembly process:

1. Glass Bonding

From windshields to side windows, glass bonding requires meticulous attention to detail. Graco’s precision dispensing equipment ensures a perfect bead every time, enhancing structural integrity and leak resistance.

2. Body Panel Assembly

Adhesives are increasingly used to attach body panels due to their ability to reduce weight while maintaining strength. Graco systems provide consistent application even with challenging materials like aluminum or composites.

3. Trim Attachment

Whether it’s interior trim or exterior moldings, Graco systems deliver precise adhesive application for a clean finish that lasts.

4. Sealing Applications

Sealing gaps to prevent moisture or dust intrusion is critical for vehicle longevity. Graco’s advanced sealing technology applies materials with pinpoint accuracy, ensuring optimal protection without excess waste.

The Competitive Edge: Why Automakers Choose Graco

Automotive manufacturers worldwide trust Graco for several reasons:

- Reliability: Built to withstand demanding production environments.

- Flexibility: Configurable systems that adapt to various materials and applications.

- Data Insights: Many Graco systems allow process data analysis for continuous improvement.

- Future-Proof Design: As electric vehicles (EVs) become more prominent, the need for lightweight materials and precise bonding will grow—areas where Graco excels.

Conclusion

In an industry where precision drives performance, Graco’s advanced sealant systems are setting new standards in automotive manufacturing. From glass bonding to body panel assembly, these solutions ensure durability while optimizing efficiency and reducing costs.

At HMFT, we’re proud to distribute these cutting-edge technologies to help automakers achieve their goals. Whether you’re looking to enhance your production line or solve specific challenges in bonding or sealing applications, we’re here to guide you every step of the way.

FAQs

1. What types of materials can Graco sealant systems handle?

Graco systems are compatible with a wide range of materials, including acrylics, epoxies, silicones, urethanes, elastomers, and polysulfides.

2. How do Graco systems reduce material waste?

By maintaining consistent flow rates and accurate ratios during dispensing, Graco equipment minimizes overuse or underuse of materials, reducing waste significantly.

3. Are these systems suitable for electric vehicle (EV) manufacturing?

Yes. As EVs require lightweight construction and precise bonding techniques, Graco’s advanced technologies are ideal for meeting these demands.

4. Can I customize a Graco system for my specific needs?

Absolutely. Many Graco solutions are modular and configurable to meet unique production requirements.

5. What maintenance support does HMFT provide?

As an authorized distributor of Graco equipment, HMFT offers full support services—including installation guidance, maintenance training, and access to replacement parts—to keep your operations running smoothly.