In the world of window manufacturing, precision is everything. Whether you're cutting aluminum, steel, or other metals for frames and components, the quality of your cuts directly impacts the durability, appearance, and performance of your windows. But achieving clean, precise cuts while minimizing waste and extending tool life can be a challenge—especially with traditional lubrication methods. That’s where Unist’s innovative lubrication systems come in. At HMFT, we’re proud to distribute Unist machining solutions across Canada, helping window manufacturers optimize their metal cutting processes with precision lubrication. Let’s dive into how Unist systems are transforming this critical step in production.

The Challenges of Metal Cutting in Window Manufacturing

Metal cutting is a key process in window manufacturing, but it comes with its own set of challenges:

- Tool Wear: Cutting tools experience significant wear and tear due to friction and heat during operation.

- Material Waste: Poor lubrication can lead to burrs, uneven cuts, or damaged materials, increasing scrap rates.

- Coolant Costs: Traditional flood coolant systems consume large amounts of fluid, driving up costs and creating messy workspaces.

- Sustainability Concerns: Excessive coolant usage and disposal can harm the environment and add regulatory burdens.

Unist lubrication systems address these challenges head-on by delivering precise amounts of lubricant exactly where it’s needed—no more, no less.

How Unist Lubrication Systems Improve Metal Cutting

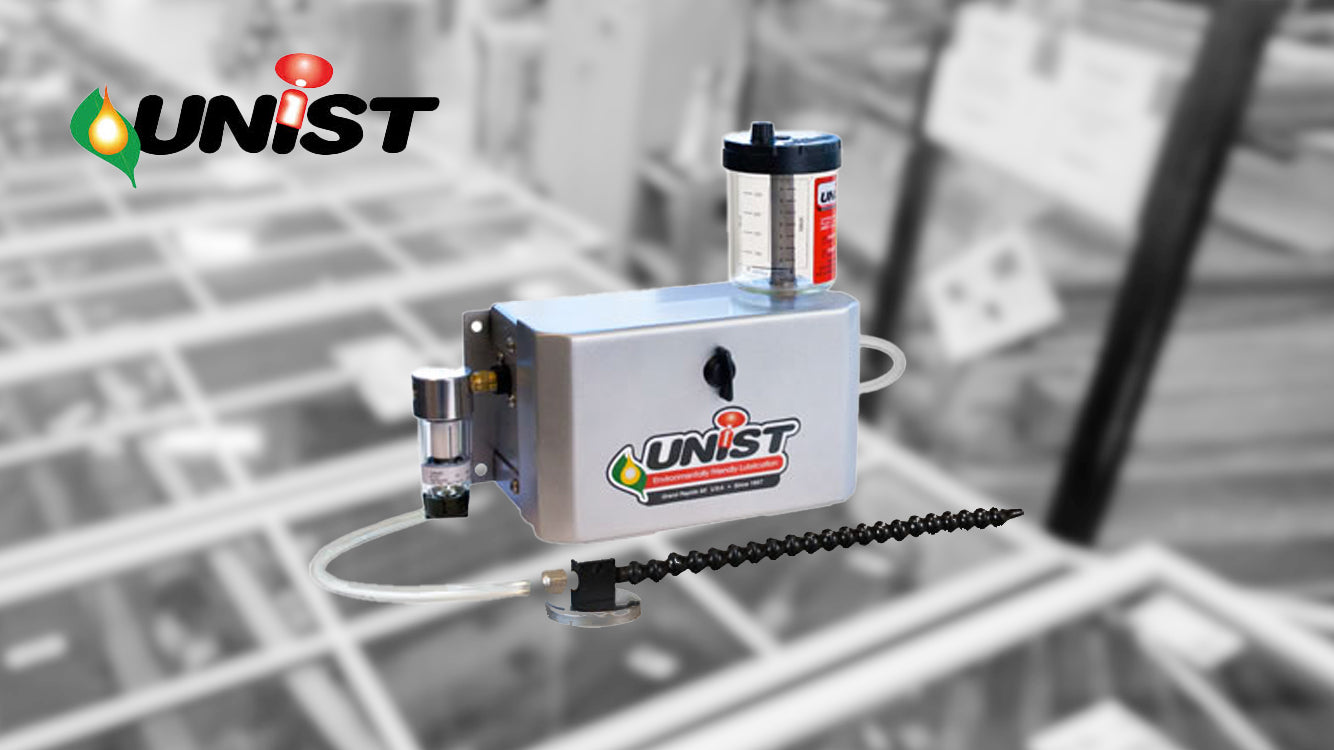

Unist’s Minimum Quantity Lubrication (MQL) technology is designed to optimize metal-cutting processes while reducing waste and costs. Here’s how it works:

1. Precise Lubricant Application

Unlike traditional flood coolant systems that drench the cutting area, Unist systems apply a fine mist or micro-droplets of lubricant directly to the tool and cutting surface. This targeted approach minimizes fluid usage while ensuring optimal lubrication for clean, precise cuts.

2. Reduced Heat and Friction

By delivering lubricant exactly where it’s needed, Unist systems reduce heat generation and friction during cutting. This not only improves cut quality but also extends tool life by preventing premature wear.

3. Cleaner Workspaces

MQL technology eliminates the mess associated with flood coolant systems. With less fluid waste and no overspray, your workspace stays cleaner and safer for operators.

4. Compatibility with Various Metals

Unist lubrication systems are versatile enough to handle a wide range of materials used in window manufacturing, including aluminum, steel, and other alloys. This makes them ideal for diverse production lines.

The Benefits of Precision Lubrication for Window Manufacturers

Integrating Unist lubrication systems into your metal-cutting processes offers several advantages:

- Improved Cut Quality: Precise lubrication ensures smooth edges and reduces burr formation.

- Extended Tool Life: Reduced friction and heat lead to longer-lasting cutting tools.

- Sustainability: Lower fluid usage aligns with eco-friendly manufacturing practices.

- Cost Savings: Less lubricant consumption reduces operating costs over time.

- Enhanced Productivity: Cleaner cuts mean fewer reworks and faster production cycles.

The HMFT Advantage: Your Partner in Precision Lubrication

At HMFT, we understand that every window manufacturer has unique needs. That’s why we work closely with you to design customized solutions using Unist lubrication systems. Our team provides expert guidance on system selection, installation, and ongoing support to ensure your operations run smoothly.

The Future of Metal Cutting in Window Manufacturing

If you’re ready to take your metal cutting operations to the next level with precision lubrication solutions from Unist, HMFT is here to help. By reducing waste, improving cut quality, and extending tool life, these systems offer a smarter way to optimize your production line—and stay ahead in a competitive industry.

Contact us today to learn more about how Unist lubrication systems can transform your metal cutting processes!

FAQ

Q: Can these systems handle high-speed cutting operations?

A: Yes! Unist lubrication systems are designed for high-speed applications, ensuring consistent performance even under demanding conditions.

Q: Are these systems compatible with CNC machines?

A: Absolutely! Unist MQL systems integrate seamlessly with CNC machines for automated precision lubrication.

Q: How much lubricant do these systems use compared to flood coolant?

A: MQL technology uses significantly less lubricant—often just a fraction of what traditional flood coolant systems require.

Q: What maintenance is required?

A: Regular cleaning of nozzles and periodic checks of fluid levels are typically all that’s needed to keep Unist systems running smoothly.

Q: Can HMFT assist with installation?

A: Yes! We provide full support during installation and ensure the system is configured correctly for your specific needs.