In the world of automotive assembly, precision isn’t just a goal—it’s a necessity. Every component, every process, and every material must meet exacting standards to ensure quality, efficiency, and sustainability. One area where precision is critical is chemical dosing, whether it’s for water treatment, paint preparation, or cooling systems. That’s where Grundfos Digital Dosing pumps come into play.

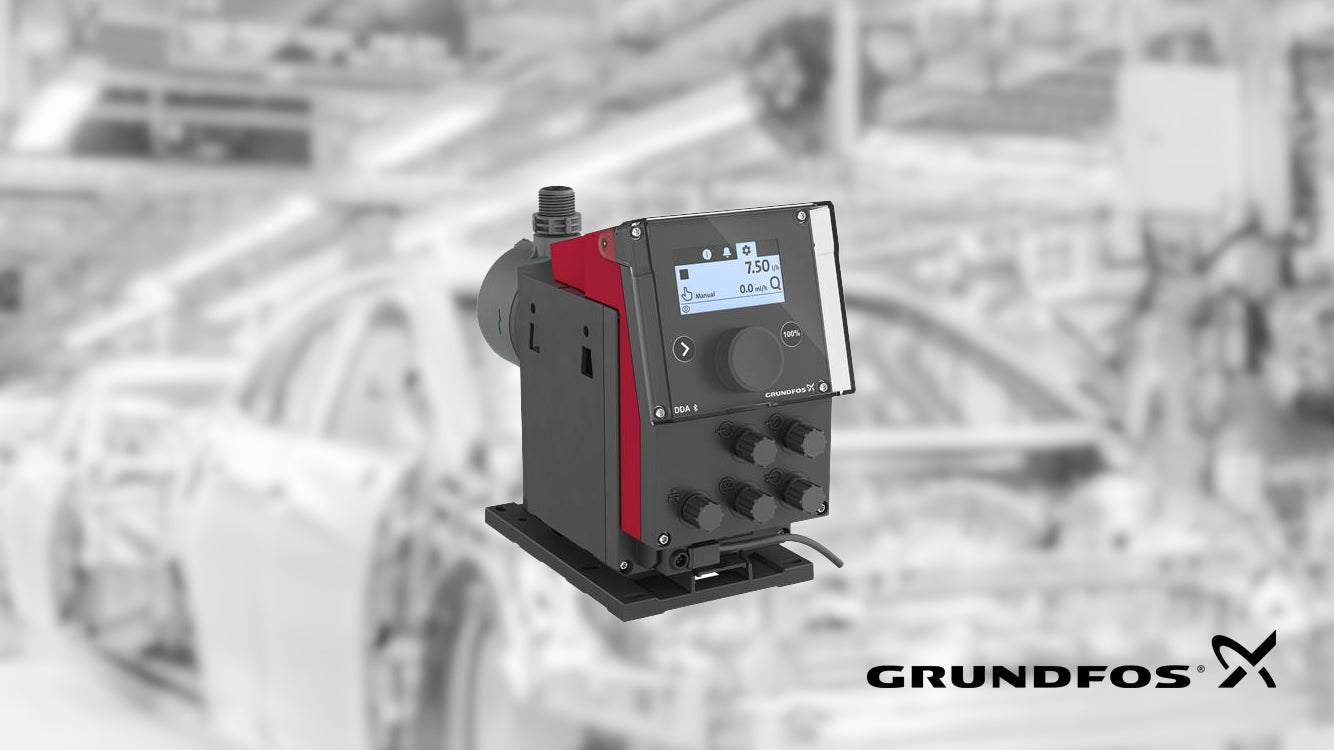

These state-of-the-art pumps are designed to deliver unmatched accuracy and reliability, ensuring that every drop of chemical is dosed precisely where it’s needed. In this blog, we’ll explore how Grundfos Digital Dosing pumps optimize chemical applications in automotive assembly plants and why they’re a game-changer for manufacturers striving for excellence.

The Importance of Precision in Chemical Dosing

Chemical dosing is a vital part of many processes in automotive manufacturing. Here are some key areas where precise dosing is essential:

- Water Treatment: Ensuring the correct balance of chemicals for boiler feedwater, cooling towers, and wastewater treatment systems is crucial to maintaining equipment efficiency and meeting environmental regulations.

- Paint Preparation: Achieving the perfect paint consistency requires precise mixing of additives and solvents to ensure a flawless finish on vehicles.

- Cooling Systems: Proper dosing of corrosion inhibitors and biocides helps protect cooling systems from scale buildup and microbial growth, extending their lifespan and improving performance.

Inaccurate dosing can lead to a host of problems, including wasted chemicals, inconsistent product quality, equipment damage, and regulatory compliance issues. That’s why automotive manufacturers need reliable solutions like Grundfos Digital Dosing pumps to get it right every time.

What Makes Grundfos Digital Dosing Pumps Stand Out?

Grundfos Digital Dosing pumps are designed to deliver precise, reliable performance in even the most demanding applications. Here’s what sets them apart:

1. Unmatched Precision

The heart of any digital dosing pump is its ability to deliver chemicals with pinpoint accuracy. Grundfos pumps achieve this through advanced stepper motor technology that ensures smooth, continuous dosing without pulsation. This level of precision minimizes waste and ensures consistent results across all applications.

2. Wide Dosing Range

Grundfos Digital Dosing pumps offer an impressive turndown ratio of up to 1:3,000. This means they can handle a wide range of dosing volumes with the same pump, making them versatile enough for various applications within an automotive assembly plant.

3. Intelligent Features

These pumps are equipped with smart features like AutoFlowAdapt and FlowControl that automatically adjust dosing rates based on system conditions. This ensures optimal performance even when there are fluctuations in pressure or flow.

4. User-Friendly Interface

The intuitive interface makes it easy for operators to set up and monitor the pump’s performance. Real-time data on flow rates, pressure levels, and chemical usage allows for quick adjustments and better control over processes.

5. Durability and Reliability

Built with high-quality materials like PVDF and PTFE, Grundfos Digital Dosing pumps are resistant to aggressive chemicals and harsh industrial environments. Their robust design ensures long-lasting performance with minimal maintenance requirements.

Applications in Automotive Assembly Plants

Grundfos Digital Dosing pumps can be seamlessly integrated into various processes within automotive manufacturing facilities:

Water Treatment Systems

From treating boiler feedwater to maintaining cooling tower chemistry, these pumps ensure precise dosing of chemicals like pH adjusters, coagulants, and biocides. This not only improves water quality but also protects equipment from corrosion and scaling.

Paint Preparation

The quality of a vehicle’s finish depends heavily on the consistency of the paint used. Grundfos Digital Dosing pumps deliver precise amounts of additives like hardeners or solvents into the paint mix, ensuring uniformity and reducing defects.

Wastewater Treatment

Treating wastewater before discharge is both an environmental responsibility and a regulatory requirement. These pumps ensure accurate dosing of neutralizing agents or flocculants to meet compliance standards while minimizing chemical waste.

Cooling System Maintenance

Dosing corrosion inhibitors or biocides into cooling systems prevents microbial growth and scale buildup that can compromise efficiency or damage equipment over time.

The Benefits for Automotive Manufacturers

By integrating Grundfos Digital Dosing pumps into their operations, automotive manufacturers can enjoy several key benefits:

- Improved Quality Control: Precise dosing ensures consistent results across all processes, enhancing product quality.

- Reduced Chemical Waste: Accurate dosing minimizes overuse or underuse of chemicals, saving money and reducing environmental impact.

- Simplified Operations: Intelligent features automate adjustments based on real-time conditions, reducing manual intervention.

- Sustainability Compliance: Efficient chemical usage aligns with environmental regulations and corporate sustainability goals.

- Lower Maintenance Costs: Durable construction reduces wear-and-tear-related downtime or repair expenses.

The HMFT Advantage: Supporting Canadian Automotive Manufacturers

If you’re looking for reliable solutions to optimize your chemical applications, HMFT is here to help. As an authorized distributor of Grundfos products in Canada, we provide expert consultation, installation support, training services, and access to replacement parts—all tailored to meet your specific needs.

No matter your challenge—whether it’s improving water treatment efficiency or achieving flawless paint finishes—we’ll work with you to implement Grundfos Digital Dosing technology that delivers results you can count on.

Conclusion

The demands of modern automotive manufacturing require precision at every step—and chemical dosing is no exception. Grundfos Digital Dosing pumps offer the accuracy, reliability, and intelligence needed to optimize processes while reducing costs and environmental impact.

If you’re ready to take your operations to the next level with cutting-edge dosing technology, contact HMFT today! Let us help you implement Grundfos solutions that enhance efficiency across your facility while supporting your commitment to quality and sustainability.

FAQ

1. What types of chemicals can Grundfos Digital Dosing pumps handle?

These pumps are compatible with a wide range of chemicals including pH adjusters, coagulants, biocides, corrosion inhibitors, solvents, hardeners, neutralizing agents, flocculants, and more.

2. How do these pumps improve chemical efficiency?

Their advanced stepper motor technology ensures accurate dosing without pulsation or overuse of chemicals—reducing waste while maintaining optimal performance.

3. Are these pumps suitable for harsh industrial environments?

Yes! Built with durable materials like PVDF (Polyvinylidene fluoride) and PTFE (Polytetrafluoroethylene), these pumps are resistant to aggressive chemicals and tough operating conditions.

4. Can these pumps integrate with existing systems?

Absolutely! Grundfos Digital Dosing pumps are designed for seamless integration into existing water treatment systems or other industrial setups with minimal modifications required.

5. Does HMFT provide installation support?

Yes! As an authorized distributor of Grundfos products in Canada, HMFT offers full installation guidance along with ongoing maintenance support to ensure peak performance from your equipment.