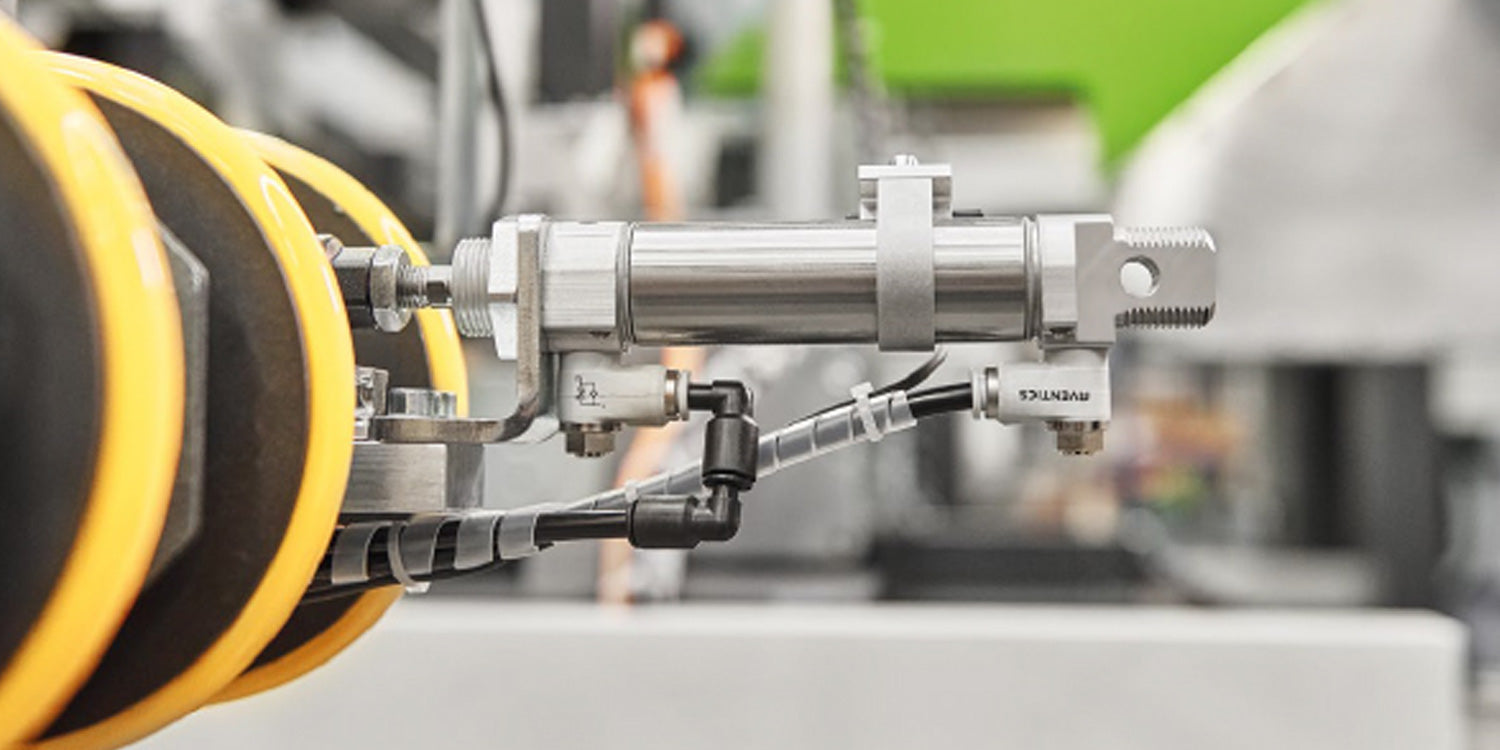

Pneumatic cylinders play a vital role in countless industrial applications, and Aventics is a trusted name in this field. To ensure these cylinders deliver peak performance and longevity, regular maintenance is crucial. In this guide, we'll walk you through the essential maintenance tips and best practices for Aventics pneumatic cylinders.

Why Proper Maintenance Matters

Proper maintenance of Aventics pneumatic cylinders is not just a recommendation; it's a necessity. Neglecting maintenance can lead to reduced efficiency, increased downtime, and costly repairs. By following these maintenance guidelines, you can extend the lifespan of your cylinders and avoid unexpected issues.

Essential Tools for Cylinder Maintenance

Before diving into the maintenance process, make sure you have the necessary tools at hand. You'll need:

- Wrenches and pliers for disassembly.

- Cleaning materials such as rags and brushes.

- Lubricants recommended by Aventics.

- A pressure gauge for testing.

Step-by-Step Maintenance Guide

Visual Inspection: Start by visually inspecting the cylinder for any signs of wear, corrosion, or damage. Check for bent rods or misalignment. Address any visible issues promptly. Lubrication: Proper lubrication is essential for smooth cylinder operation. Apply the recommended lubricant to the piston rod and seals. This reduces friction and extends the life of the seals.

Sealing Check: Inspect the cylinder's seals for wear, cracks, or leaks. Damaged seals can lead to air leakage and reduced efficiency. Replace any faulty seals with genuine Aventics parts. Pressure Testing: To ensure the cylinder operates within the specified parameters, conduct a pressure test. This helps identify any internal leaks or pressure fluctuations. If issues arise, consult Aventics' technical support for further guidance.

Troubleshooting Common Cylinder Issues

Even with regular maintenance, issues can arise. Here are some common problems and their solutions:

- Slow Cylinder Movement: Check for insufficient lubrication or seal damage.

- Excessive Noise: Inspect for loose components or misalignment.

- Leaking Air: Replace damaged seals or check for loose fittings.

- Uneven Movement: Verify proper alignment and rod condition.

Safety Considerations

Always prioritize safety when working with pneumatic cylinders. Before maintenance, shut off the air supply, and ensure the system is depressurized. Use proper safety gear, and follow Aventics' safety guidelines throughout the maintenance process.

Regular maintenance is the key to ensuring the longevity and efficiency of Aventics pneumatic cylinders. By following the steps outlined in this guide and addressing issues promptly, you can minimize downtime and maximize the performance of your equipment. Remember, your satisfaction is our commitment.