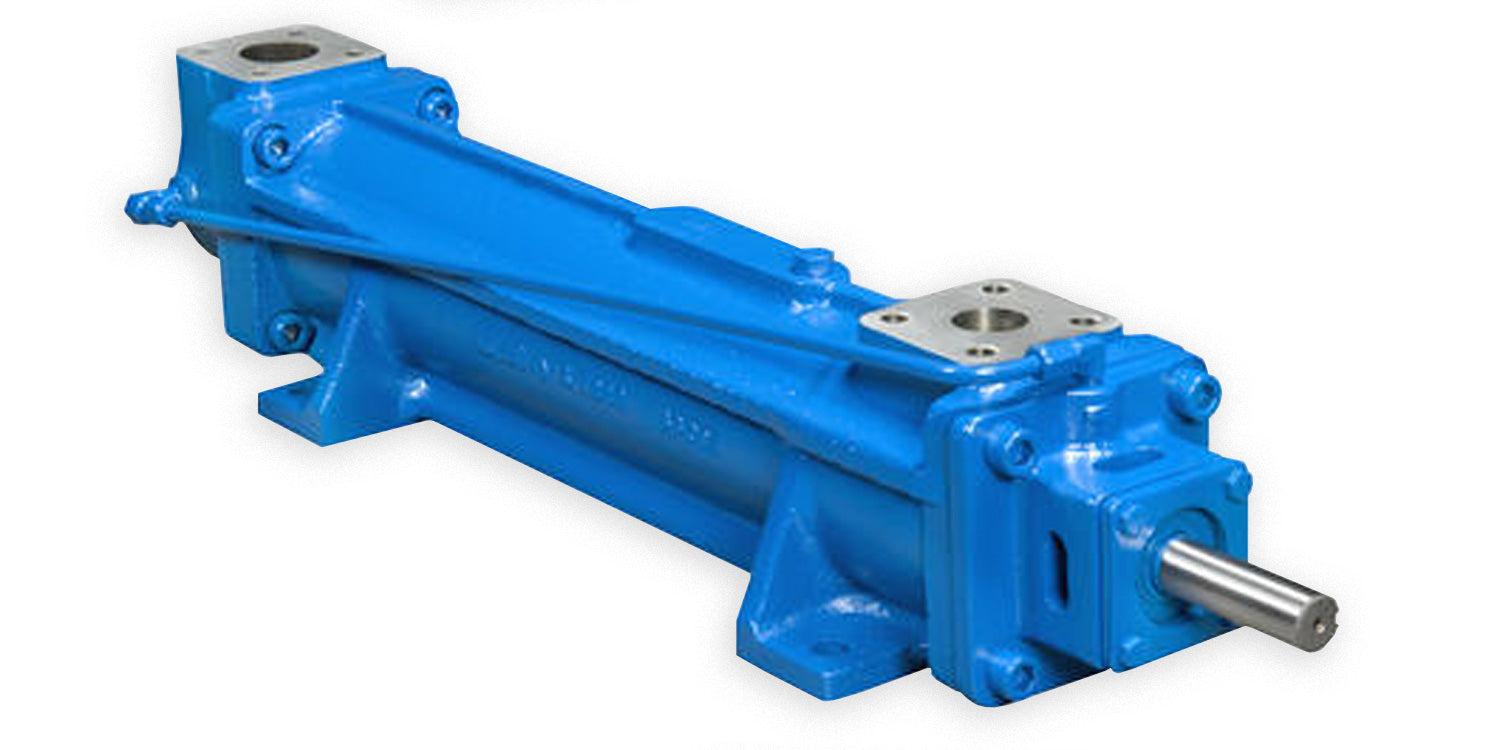

On the landscape of industrial machinery, the IMO Three-Screw Pump stands as a hallmark of efficiency and robust performance. However, like any mechanical asset, the secret to its longevity and optimal performance lies in diligent maintenance. Through a regimented maintenance schedule, operators can avoid the pitfalls of unexpected downtime and costly repairs, ensuring a streamlined operation and long-term financial savings.

Routine Inspection and Maintenance

At the heart of preventive maintenance is routine inspection. Regular checks for leaks are imperative as they could be indicative of seal issues or other underlying problems. Monitoring the pressure and temperature helps in averting operational anomalies. It's advisable to maintain a log to track any deviations over time.

Lubrication is the lifeblood of the IMO Three-Screw Pump. Ensuring that the pump is adequately lubricated minimizes wear and extends its life span. Cleaning, on the other hand, prevents the accumulation of debris which can hinder the pump’s performance.

Furthermore, replacing worn parts promptly is crucial. Delaying replacements can lead to severe damage and, consequently, more expensive repairs.

Advanced Maintenance Techniques

As operations evolve, so does the necessity for advanced maintenance techniques. Vibration analysis can be an invaluable tool in identifying issues before they morph into major problems. Similarly, alignment checks ensure that the pump operates smoothly, reducing the wear on the components.

Performance monitoring is another avenue to gauge the health of your IMO Three-Screw Pump. Modern technology affords a plethora of tools to monitor and analyze the pump’s performance, aiding in timely interventions.

Professional Services for Optimal Performance

There are instances when the expertise of professionals is indispensable. Professional maintenance services are adept at diagnosing and rectifying complex issues, thus ensuring that your pump operates at peak efficiency. Their experience also translates to quicker resolution of problems, minimizing downtime.

A stitch in time, as they say, saves nine. The same holds true for maintaining your IMO Three-Screw Pump. A meticulous maintenance routine, coupled with advanced techniques and professional services when necessary, is the bedrock of ensuring longevity and efficiency of your industrial asset.

At HMFT, we pride ourselves on more than just selling top-quality products. We boast a team of technical experts intimately familiar with the products we offer. Beyond that, our trained service technicians are equipped with the skills and experience to handle installation, repairs, and routine maintenance, ensuring our customers enjoy the full potential and longevity of their purchases. Your satisfaction, backed by our expertise, is our commitment.