At HMFT, we understand how critical it is to maintain the efficiency and longevity of steam turbines in the power generation industry. One of the most overlooked yet crucial aspects of turbine maintenance is the quality of the lubricating oil. Today, we want to dive into how Hilco Coalescer Separators can be a game-changer for your steam turbine lube oil systems.

The Importance of Clean Lube Oil

Steam turbines are the workhorses of many power plants, converting thermal energy into mechanical energy to drive generators. To function optimally, these turbines rely on a continuous supply of clean, high-quality lubricating oil. However, lube oil is constantly under attack from contaminants like water and particulates, which can severely impact turbine performance and lifespan.

The Consequences of Contaminated Oil

- Reduced efficiency

- Increased wear on bearings and other components

- Higher maintenance costs

- Potential for unexpected downtime

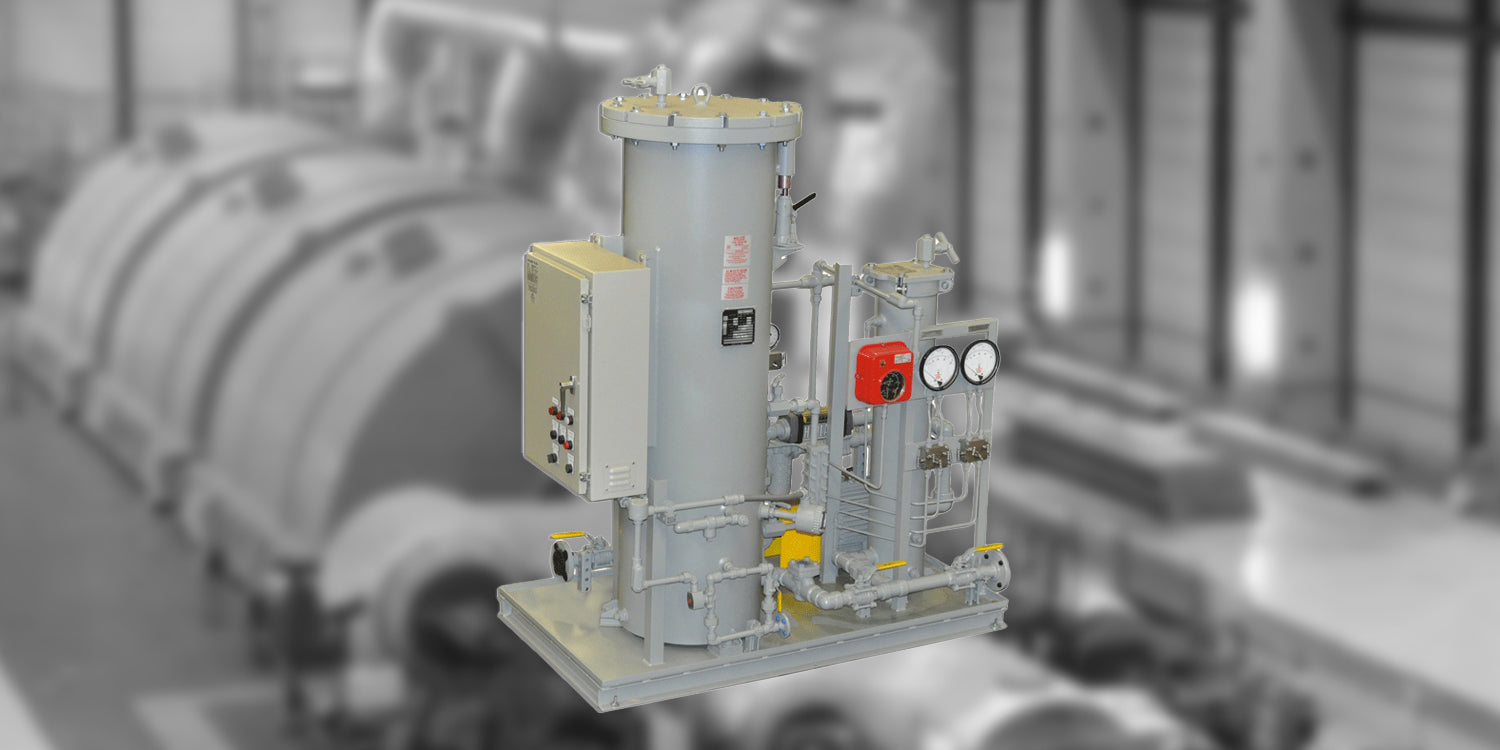

Enter the Hilco Coalescer Separator

The Hilco Coalescer Separator is a powerful solution designed specifically to tackle the challenges of maintaining clean lube oil in steam turbine systems. Let's explore how this innovative technology works and why it's becoming an essential tool for power generation facilities.

How Coalescer Separators Work

- Coalescence: The separator uses specially designed media to cause small water droplets to combine into larger ones.

- Separation: These larger water droplets are then easily separated from the oil due to the difference in density.

- Filtration: Simultaneously, the system removes solid particulates from the oil.

Key Benefits of Hilco Coalescer Separators

- Moisture Removal: Reduces free and emulsified water content to under 25 ppm.

- Particulate Filtration: Achieves 99.5% efficiency at removing particles as small as 3 microns.

- Extended Oil Life: By keeping the oil clean and dry, these separators can significantly extend the life of your turbine oil.

- Improved Efficiency: Clean oil means less friction and better heat transfer, leading to improved turbine efficiency.

- Reduced Maintenance: With cleaner oil, you'll see less wear on turbine components, reducing the need for repairs and replacements.

Implementing Hilco Coalescer Separators in Your Plant

Integrating a Hilco Coalescer Separator into your steam turbine lubrication system is a smart investment. Here's why:

- Cost-Effective: While there's an upfront cost, the long-term savings in oil replacement, maintenance, and improved efficiency make it a wise financial decision.

- Versatile: Hilco offers various models to suit different turbine sizes and oil volumes, from 2,000 to 12,000+ gallon reservoirs.

- Easy Integration: These systems can be easily incorporated into existing lubrication systems, often as a side-stream filtration setup.

- Continuous Operation: Unlike some filtration methods, coalescer separators can operate continuously, providing round-the-clock protection for your turbine oil.

Best Practices for Optimal Results

To get the most out of your Hilco Coalescer Separator:

- Regular Monitoring: Implement a routine oil analysis program to track the improvement in oil quality over time.

- Proper Sizing: Work with HMFT experts to ensure you select the right size separator for your specific turbine and oil volume.

- Maintenance Schedule: While these systems are low-maintenance, regular checks and filter replacements will ensure optimal performance.

- Staff Training: Educate your team on the importance of oil cleanliness and how to operate and monitor the separator system effectively.

Conclusion

In the competitive world of power generation, every efficiency gain counts. By implementing Hilco Coalescer Separators in your steam turbine lube oil systems, you're not just maintaining oil quality – you're investing in the longevity and performance of your turbines. Clean oil means more uptime, lower maintenance costs, and improved overall efficiency.

Don't let contaminated lube oil be the weak link in your power generation process. Explore how Hilco Coalescer Separators can revolutionize your turbine maintenance strategy and keep your plant running at peak performance.

FAQ Section

- How often should I replace the filters in a Hilco Coalescer Separator?

- The frequency depends on your specific operating conditions, but typically, filters should be checked monthly and replaced as needed based on pressure drop or oil analysis results.

- Can a Hilco Coalescer Separator be used with other types of turbines besides steam turbines?

- Yes, while particularly effective for steam turbines, these separators can also be used with gas turbines and other industrial equipment requiring clean oil.

- What's the typical return on investment for installing a Hilco Coalescer Separator?

- While it varies, many plants see a return on investment within 1-2 years through reduced oil replacement costs, lower maintenance expenses, and improved turbine efficiency.

- How does the Hilco Coalescer Separator compare to other oil cleaning methods?

- Compared to traditional methods, the Hilco system offers superior water and particulate removal efficiency, continuous operation capability, and the ability to handle both free and emulsified water effectively.