In the window manufacturing industry, selecting the right sealant system is critical to ensuring durable, energy-efficient, and aesthetically pleasing windows. Whether you're sealing insulating glass units or bonding corner joints, the choice between hot melt and ambient sealant systems can significantly impact your production efficiency and product quality. At HMFT, we’re proud to distribute Graco’s advanced sealant equipment across Canada, helping manufacturers optimize their operations. Today, we’ll explore the key differences between hot melt and ambient sealants and how Graco systems can meet your unique needs.

Understanding Hot Melt Sealants

Hot melt sealants are thermoplastic adhesives that are heated to a liquid state before application. Once applied, they cool and solidify quickly to form a strong bond. These sealants are widely used in applications requiring fast curing times and high initial strength.

Benefits of Hot Melt Sealants

- Fast Curing: Hot melt sealants solidify within seconds, speeding up production cycles.

- Strong Bonds: They provide excellent adhesion to a variety of substrates, including glass, metal, and vinyl.

- Durability: Hot melt sealants are resistant to moisture and temperature fluctuations, making them ideal for insulating glass units.

- Clean Application: Their quick setting reduces the risk of smearing or dripping during assembly.

Ideal Applications

Hot melt sealants are perfect for high-speed production lines where quick curing is essential, such as sealing double or triple-pane insulating glass units.

Understanding Ambient Sealants

Ambient sealants are applied at room temperature without the need for heating systems. These sealants cure over time through chemical processes like evaporation or polymerization. They are often used in applications requiring flexibility and longer working times.

Benefits of Ambient Sealants

- Ease of Use: No heating equipment is required, simplifying setup and reducing energy costs.

- Flexibility: Ambient sealants remain pliable after curing, accommodating movement and thermal expansion in window assemblies.

- Sustainability: Many ambient sealants are low-VOC formulations, aligning with eco-friendly manufacturing practices.

- Longer Working Times: Extended curing times allow for adjustments during assembly.

Ideal Applications

Ambient sealants are best suited for applications like bonding corner joints or sealing frames where flexibility and adjustability are required.

The Graco Advantage: Hot Melt vs. Ambient Systems

No matter which type of sealant you choose, Graco offers cutting-edge equipment designed to optimize your application process. Here’s how their systems compare:

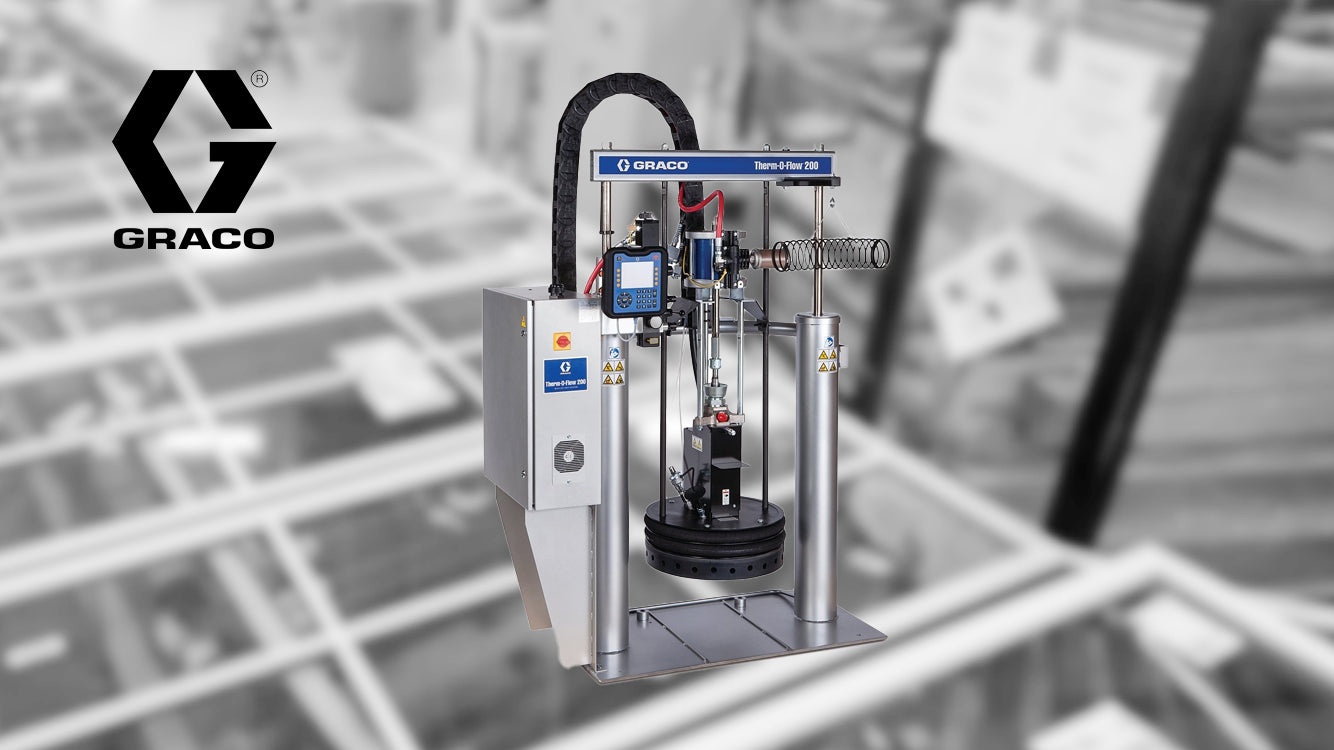

| Feature | Graco Hot Melt Systems (e.g., Therm-O-Flow) | Graco Ambient Systems (e.g., ExactaBlend AGP) |

|---|---|---|

| Curing Speed | Instantaneous | Gradual |

| Energy Efficiency | Requires heating equipment | No heating required |

| Sustainability | Low waste due to precise application | Low-VOC formulations available |

| Applications | Insulating glass sealing | Corners and frame bonding |

Selecting the Right System for Your Needs

The choice between hot melt and ambient systems depends on your specific production requirements. Here are some factors to consider:

- Production Speed: If you need fast curing times for high-volume production, hot melt systems like Graco’s Therm-O-Flow are ideal.

- Sustainability Goals: For eco-friendly operations, ambient systems with low-VOC sealants may be a better fit.

- Application Type: Consider whether your process requires rigid bonds (hot melt) or flexible seals (ambient).

- Budget: Ambient systems typically have lower upfront costs due to the lack of heating equipment.

The HMFT Advantage: Expert Guidance Every Step of the Way

At HMFT, we understand that every window manufacturer has unique needs. That’s why we work closely with you to identify the right Graco system for your operations. Our team provides expert advice on equipment selection, installation, and maintenance to ensure your production line runs smoothly.

The Future of Sealant Application in Window Manufacturing

If you’re ready to optimize your window production line with advanced sealant systems from Graco, HMFT is here to help. Whether you need the speed of hot melt or the flexibility of ambient solutions, we’ll guide you toward the perfect fit for your operations—because when it comes to quality and efficiency, there’s no room for compromise.

Contact us today to learn more about how Graco’s sealant equipment can transform your manufacturing process!

FAQ

Q: Can I use both hot melt and ambient systems in my facility?

A: Yes! Many manufacturers use a combination of systems for different applications within their production lines.

Q: Are Graco systems compatible with automated setups?

A: Absolutely! Graco’s equipment integrates seamlessly with automated production lines for efficient dispensing.

Q: Which system is more cost-effective?

A: It depends on your specific needs. Hot melt systems may offer faster throughput but require heating equipment, while ambient systems have lower upfront costs.

Q: Can HMFT assist with installation?

A: Yes! We provide full support during installation and ensure the system is configured correctly for your processes.

Q: How do I maintain these systems?

A: Regular cleaning and inspection of nozzles and hoses will keep both hot melt and ambient systems running efficiently.