In today’s fast-paced manufacturing world, flexibility and efficiency are more important than ever. For machinery manufacturers, meeting diverse customer demands often means switching between different colours and finishes quickly and seamlessly. This is where Nordson’s advanced powder coating systems, like the ColorMax®2 Booth and Color-On-Demand System, shine. These innovative solutions are designed to perform ultra-fast, contamination-free colour changes, helping manufacturers boost productivity while maintaining impeccable quality.

Let’s explore how Nordson’s fast colour change technology is revolutionizing powder coating for machinery manufacturers.

The Challenge: Meeting Diverse Colour Demands Without Downtime

Machinery manufacturers often face a unique challenge: balancing high production volumes with the need to accommodate custom colour requirements. Whether it’s for branding purposes or specific customer requests, being able to switch between colours without significant downtime is critical. Traditional powder coating systems often struggle with:

- Extended Cleaning Times: Switching colours can take hours due to the need for thorough cleaning to prevent contamination.

- Material Wastage: Inefficient systems lead to wasted powder during transitions.

- Production Delays: Long colour changeovers slow down production schedules, reducing overall throughput.

Nordson addresses these challenges head-on with their cutting-edge fast colour change solutions.

How Nordson’s Technology Revolutionizes Colour Changes

1. Colour-On-Demand System: Precision Meets Speed

Nordson’s Color-On-Demand System is a game-changer for manufacturers handling multiple colours in small batches. This system allows for automated colour changes in less than 20 seconds—yes, you read that right! Here’s how it works:

- HDLV® Technology: High-density, low-velocity powder transport minimizes air usage while maximizing powder density, enabling precise application and faster cleaning.

- Self-Cleaning Pumps: The system automatically purges the entire feed line from the hopper to the spray gun, eliminating manual cleaning.

- 28-Colour Capacity: Operators can select from up to 28 colours on-demand using an intuitive touchscreen interface.

By drastically reducing downtime and material waste, this system empowers manufacturers to meet just-in-time production requirements without sacrificing quality.

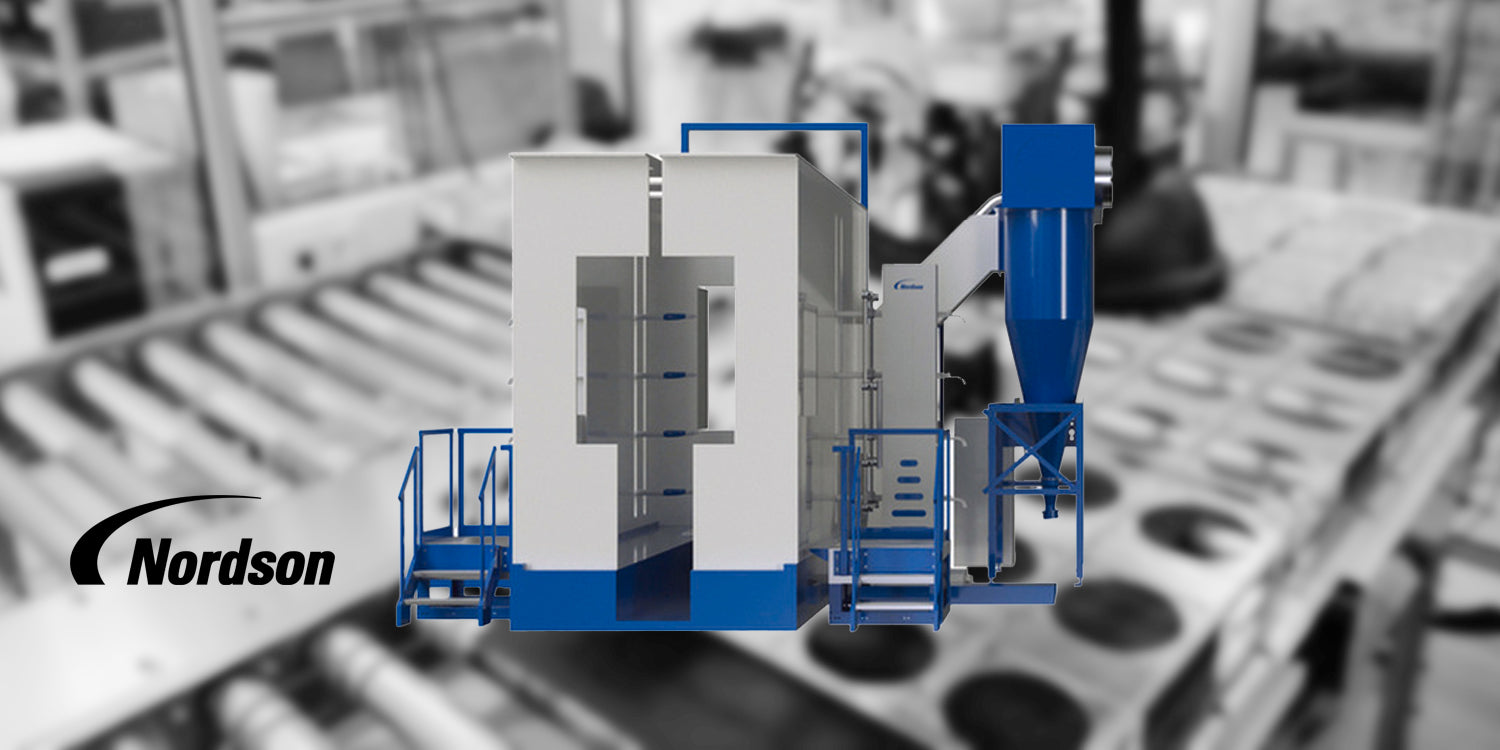

2. ColorMax®2 Booth: Designed for Efficiency

The ColorMax®2 Powder Coating Booth is another standout solution from Nordson. Engineered for rapid, contamination-free colour changes in under 10 minutes, it includes:

- Non-Conductive Booth Materials: Patented Apogee® composite materials minimize powder retention, making cleaning quicker and easier.

- Twin Cyclone Design: Facilitates complete cleaning of all surfaces with hinged sections for easy access.

- AeroWash™ Base Cleaning System: Prevents powder build-up in hard-to-reach areas.

This booth also features advanced airflow management and optimized powder recovery systems, ensuring minimal waste and consistent coating quality.

3. Lean Cell Booths: Compact and Flexible

For manufacturers with space constraints or smaller production lines, Nordson’s Lean Cell Powder Coating Booth offers a compact yet powerful solution:

- 20-Second Colour Change: Ideal for high-mix, low-volume production environments.

- Open-Face Canopy Design: Provides maximum operator access while maintaining excellent powder containment.

- Customizable Configurations: Accommodates both manual and automated processes, making it versatile for various applications.

With its innovative design and efficient operation, the Lean Cell Booth is perfect for machinery manufacturers looking to maximize productivity in limited spaces.

Why Fast Colour Changes Matter in Machinery Manufacturing

Implementing Nordson’s fast colour change systems can have a profound impact on your manufacturing operations:

- Increased Throughput: Rapid colour changes mean less downtime and more time spent producing.

- Enhanced Flexibility: Easily switch between short runs of custom colours or large-scale production batches without missing a beat.

- Cost Savings: Reduced material waste and lower energy consumption translate into significant cost reductions over time.

- Consistent Quality: Advanced technology ensures every part receives a flawless finish, regardless of the colour or complexity of the design.

For machinery manufacturers catering to diverse industries—from construction equipment to precision CNC tools—these benefits are invaluable.

HMFT’s Role in Your Success

At HMFT, we’re proud to be your trusted distributor of Nordson powder coating equipment. We understand the unique needs of machinery manufacturers and are here to help you find the perfect solution for your operations. Here’s how we support you:

- Expert Consultation: Our team will guide you through selecting the right system based on your production requirements.

- Comprehensive Support: From installation to maintenance, we provide end-to-end support to ensure your equipment operates at peak performance.

- Custom Solutions: Need something tailored? We’ll work with you to develop customized configurations that fit your specific needs.

With HMFT by your side, you’ll not only gain access to industry-leading Nordson technology but also a partner dedicated to your success.

Conclusion

Nordson’s fast colour change solutions are transforming how machinery manufacturers approach powder coating. By combining speed, precision, and efficiency, these systems enable businesses to stay competitive in an increasingly demanding market. Whether you’re looking for ultra-fast automated solutions or compact booths for smaller operations, there’s a Nordson system that fits your needs perfectly.

At HMFT, we’re here to help you unlock the full potential of this game-changing technology. Contact us today to learn more about how we can help you revolutionize your finishing processes!

FAQ

Q: How does Nordson ensure contamination-free colour changes?

A: Nordson systems feature self-cleaning HDLV pumps, advanced airflow management, and non-conductive booth materials that minimize powder retention and prevent cross-contamination during colour transitions.

Q: What industries benefit most from Nordson’s fast colour change technology?

A: While ideal for machinery manufacturing, these systems are also widely used in automotive, appliances, furniture, and other industries requiring high-quality finishes with frequent colour changes.

Q: Can small-scale manufacturers afford Nordson's advanced systems?

A: Yes! Systems like the Lean Cell Booth are designed with cost-efficiency in mind and are perfect for smaller operations looking to improve productivity without breaking the bank.

Q: How much time can I save with Nordson's Color-On-Demand System?

A: The system performs automated colour changes in less than 20 seconds—dramatically reducing downtime compared to traditional methods that can take hours.

Q: What maintenance is required for these systems?

A: Minimal maintenance is needed thanks to features like self-cleaning pumps and automated filter maintenance systems. HMFT also offers ongoing support to keep your equipment running smoothly.