In power generation facilities, hydraulic systems are the backbone of critical operations. From controlling turbine lubrication systems to regulating pressure in hydraulic circuits, these systems must operate flawlessly under extreme conditions. However, without proper pressure relief mechanisms, hydraulic systems are vulnerable to overpressure events that can lead to equipment damage, costly downtime, and even safety hazards.

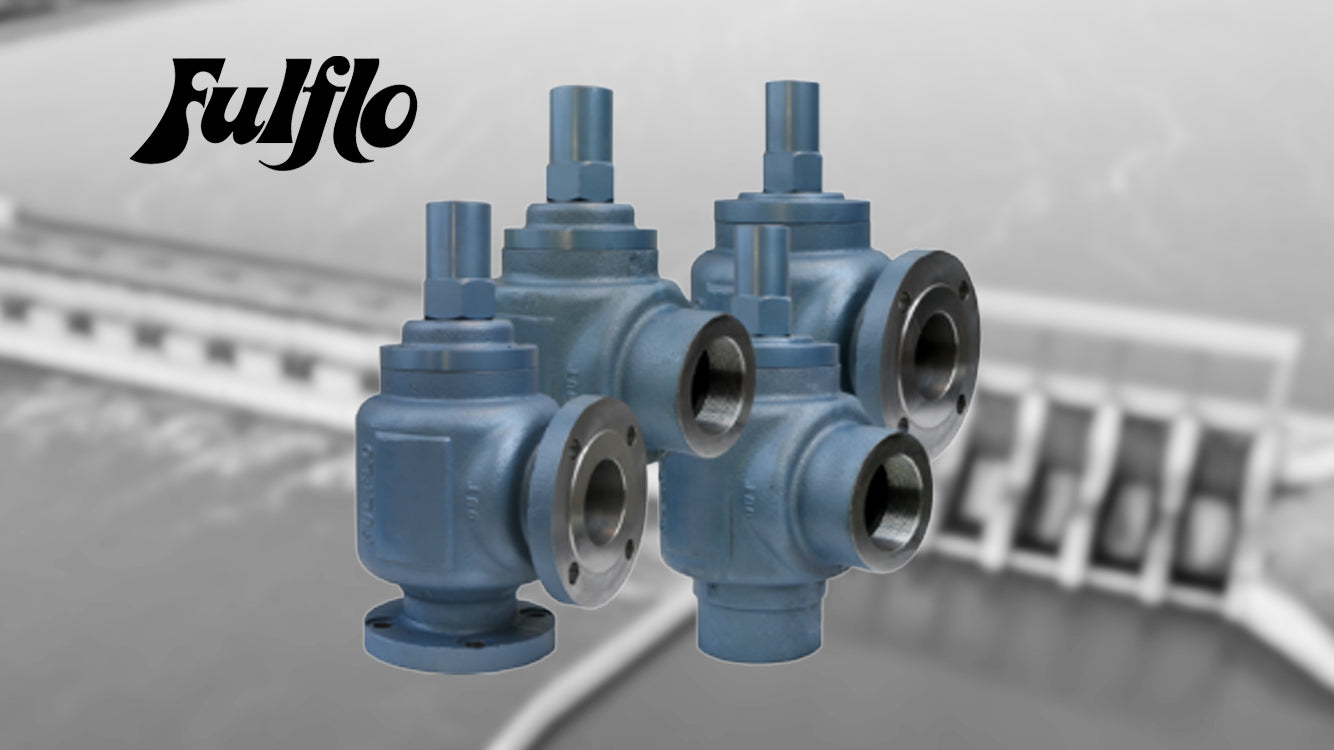

At HMFT, we understand the importance of reliable pressure control in power plants. That’s why Fulflo valves have become a trusted solution for ensuring hydraulic system reliability. In this blog, we’ll explore how Fulflo valves protect and optimize hydraulic systems in power generation facilities.

The Role of Hydraulic Systems in Power Plants

Hydraulic systems play a vital role in power generation processes by enabling precise control of fluid flow and pressure. They are commonly used in:

- Turbine Lubrication Systems: Ensuring consistent oil flow to bearings and other critical components.

- Steam Control Systems: Regulating steam pressure for optimal turbine performance.

- Hydroelectric Applications: Managing water flow and pressure in dam operations and penstocks.

- Fuel Delivery Systems: Controlling the flow of liquid or gas fuels to combustion chambers.

Given their importance, hydraulic systems must be safeguarded against overpressure conditions that could compromise their performance or cause catastrophic failures. This is where Fulflo valves come into play.

How Fulflo Valves Ensure Hydraulic System Reliability

1. Overpressure Protection

Fulflo valves act as a fail-safe mechanism by relieving excess pressure in the hydraulic system when it exceeds a preset limit. This prevents damage to pumps, pipes, seals, and other components caused by overpressure events.

Example: In turbine lubrication systems, Fulflo valves maintain stable oil pressure to prevent bearing damage during load fluctuations or startup conditions.

2. Smooth Operation with Guided Piston Technology

Unlike conventional spring-loaded relief valves, Fulflo valves use guided piston technology for precise and stable operation. The sliding piston design eliminates valve chatter during transient pressure surges, ensuring smooth relief without system instability.

Benefit: Reduced wear and tear on system components due to consistent pressure control.

3. High Pressure Capability

Fulflo valves are engineered to handle high-pressure applications common in power plants, with models capable of operating at pressures up to 1000 PSI (69 bar). This makes them ideal for demanding environments like steam turbines and hydraulic circuits under heavy loads.

4. Versatility Across Fluid Types

Power plants often deal with a variety of fluids, including hydraulic oils, water, solvents, and chemicals. Fulflo valves are compatible with diverse fluid types, ensuring reliable performance across multiple applications within the facility.

5. Durable Construction for Long-Term Reliability

Fulflo valves are built with robust materials such as stainless steel and brass to withstand harsh operating conditions like high temperatures and corrosive environments often found in power plants. Their durability translates into longer service life and reduced maintenance costs over time.

Best Practices for Integrating Fulflo Valves into Hydraulic Systems

To maximize the benefits of Fulflo valves in your power plant’s hydraulic systems, follow these best practices:

- Proper Valve Sizing: Choose a valve size that matches your system’s flow rate and pressure requirements to ensure optimal performance without excessive velocity loss or cavitation risks.

- Regular Maintenance: Periodically inspect and clean the valve components to prevent debris buildup that could affect operation efficiency.

- Material Selection: Opt for corrosion-resistant materials like stainless steel if your system operates in wet or corrosive environments (e.g., hydroelectric facilities).

- Pressure Calibration: Set the valve’s relief pressure accurately based on your system’s operating parameters to avoid premature or delayed activation during overpressure events.

Why Choose Fulflo Valves for Power Generation Facilities?

Fulflo valves offer several advantages that make them ideal for hydraulic systems in power plants:

- Precision Pressure Control: Guided piston technology ensures accurate relief without valve chatter or instability.

- Wide Application Range: Suitable for diverse applications like turbine lubrication, steam control, fuel delivery, and water management.

- Durability: Built to withstand high pressures, extreme temperatures, and corrosive environments.

- Cost Efficiency: Long service life reduces maintenance costs while minimizing downtime risks.

At HMFT, we’ve seen firsthand how Fulflo valves enhance system reliability across power generation facilities of all sizes.

Conclusion

Hydraulic systems are critical to the smooth operation of power generation facilities—but they’re only as reliable as their weakest component. By integrating Fulflo valves into your hydraulic circuits, you can protect against overpressure events, optimize fluid control, and extend the lifespan of your equipment.

At HMFT, we specialize in providing tailored solutions using industry-leading products like Fulflo valves to meet the unique needs of power plants worldwide. Contact us today to learn more about how we can help safeguard your hydraulic systems with precision-engineered pressure relief solutions.

FAQ Section

What makes Fulflo valves unique compared to traditional relief valves?

- Fulflo valves use guided piston technology instead of spring-loaded designs, ensuring smoother operation without valve chatter during transient pressure surges.

Can Fulflo valves handle high-pressure applications?

- Yes! Many models are rated for pressures up to 1000 PSI (69 bar), making them suitable for demanding environments like steam turbines and heavy-load hydraulic circuits.

Are Fulflo valves compatible with different types of fluids?

- Absolutely! Fulflo valves work reliably with hydraulic oils, water, solvents, chemicals, and other fluids commonly used in power generation facilities.

How often should I perform maintenance on Fulflo valves?

- Regular inspections every 6–12 months are recommended to ensure optimal performance and prevent debris buildup that could affect operation efficiency.

Can I use Fulflo valves in corrosive environments?

- Yes! Many models feature corrosion-resistant materials like stainless steel or brass that are ideal for wet or chemically aggressive conditions.