In the world of industrial painting and finishing, the airflow style of a paint booth plays a critical role in determining its efficiency and cost-effectiveness. Crossdraft airflow, offered by Global Finishing Solutions (GFS), is a popular choice due to its affordability and ease of integration. This article explores the benefits of crossdraft airflow in various types of paint booths.

What is Crossdraft Airflow?

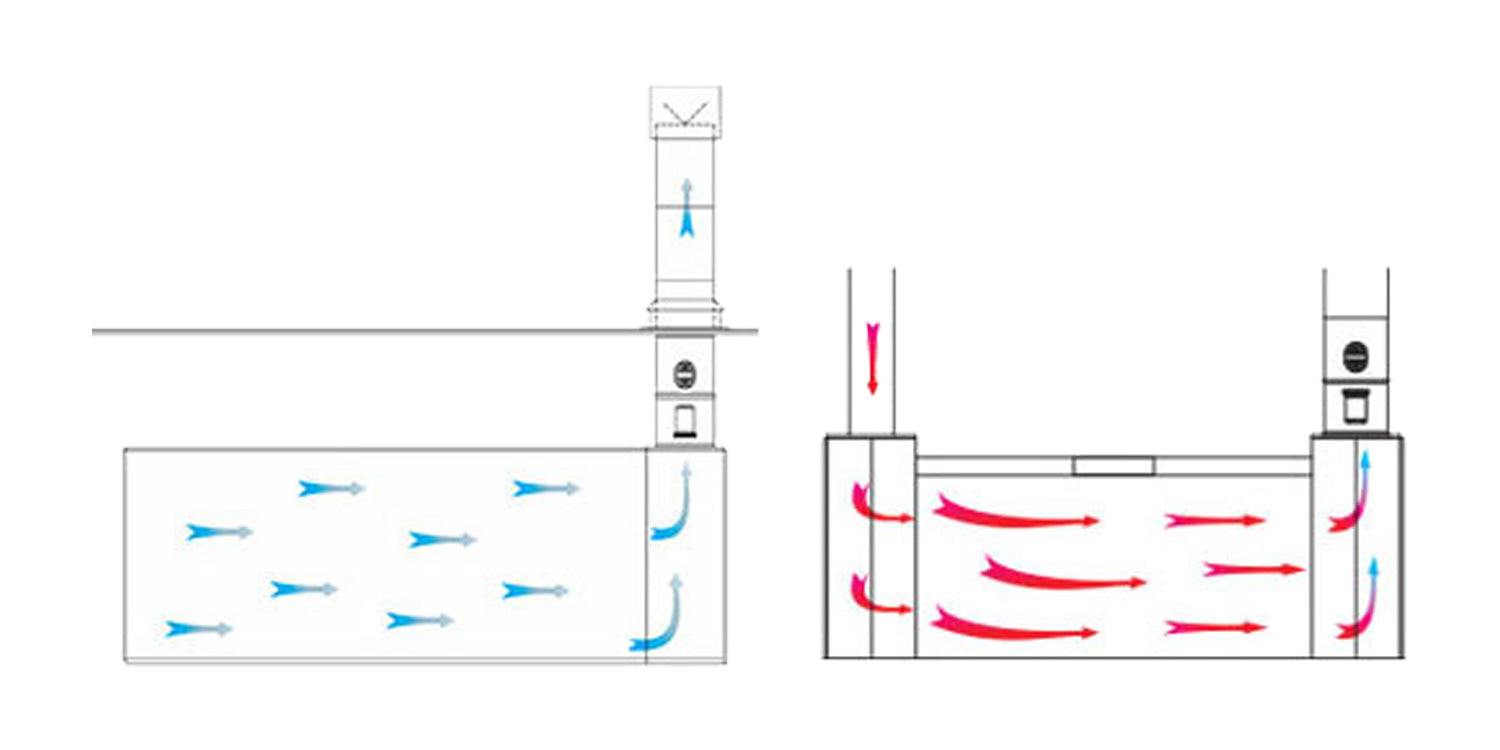

Crossdraft airflow refers to the movement of air across the length of the paint booth, from the front to the back. This airflow style eliminates the need for a pit, making it easier and more cost-effective to install in existing facilities.

Benefits of Crossdraft Airflow:

- Cost-Effectiveness: Crossdraft booths are generally more affordable than their downdraft counterparts. This makes them a viable option for businesses looking to minimize initial investment costs.

- Ease of Integration: Without the need for a pit, crossdraft booths can be easily installed in a variety of settings, including those with limited space or existing structures.

- Versatility: This airflow style is compatible with several booth types, including Bench Booths, Open Face Booths, and Enclosed Finishing Booths.

- Efficient Air Movement: In crossdraft booths, air enters from the front, flows horizontally over the product, and exits through a filter bank at the rear. This setup ensures consistent airflow across the entire product being painted.

Types of Booths with Crossdraft Airflow:

- Bench Booths: Ideal for smaller items, these booths allow unfiltered air to enter at the front and flow horizontally across the workpiece.

- Open Face Booths: These booths offer an open and accessible design, with air entering from the front and moving across the work area.

- Enclosed Finishing Booths: In these booths, air enters through filtered product doors, ensuring a cleaner airflow while still maintaining the efficiency of the crossdraft system.

Crossdraft airflow in paint booths offers a blend of cost-efficiency, ease of installation, and versatility, making it an excellent choice for a wide range of industrial painting and finishing applications. By understanding the benefits and applications of crossdraft airflow, businesses can make informed decisions that align with their operational needs and budget constraints.

At HMFT, we pride ourselves on more than just selling top-quality products. We boast a team of technical experts intimately familiar with the products we offer. Beyond that, our trained service technicians are equipped with the skills and experience to handle installation, repairs, and routine maintenance, ensuring our customers enjoy the full potential and longevity of their purchases. Your satisfaction, backed by our expertise, is our commitment.