When it comes to liquid finishing processes, selecting the right paint booth is crucial for achieving high-quality results, maintaining efficiency, and ensuring compliance with safety and environmental standards. Global Finishing Solutions (GFS) offers a wide range of paint booths tailored to meet the diverse needs of industrial manufacturers. But how do you determine which GFS booth is the best fit for your operations? Let’s dive into the key factors to consider and how GFS booths can be customized to suit your unique requirements.

Why the Right Paint Booth Matters

A paint booth isn’t just a workspace; it’s an integral part of your finishing process. The right booth ensures:

- Consistent Quality: Proper airflow, filtration, and lighting create an environment that minimizes contamination and overspray.

- Efficiency: Streamlined operations reduce downtime and material waste.

- Safety: A well-designed booth protects workers from harmful fumes and ensures compliance with industry regulations.

- Sustainability: Modern booths are designed to reduce energy consumption and emissions, aligning with eco-friendly practices.

With so much at stake, choosing the right booth is a decision that can significantly impact your bottom line.

Types of GFS Booths for Liquid Finishing

GFS offers a variety of booth styles, each designed to address specific finishing needs:

1. Open Face Paint Booths

These booths are ideal for applications where only one side of the product requires finishing. Features include:

- Modular designs that can be customized to virtually any size or configuration.

- Heavy-duty galvanized steel construction for durability.

- Efficient exhaust systems with easy-to-replace filters to capture overspray.

2. Enclosed Finishing Booths

For more comprehensive finishing needs, enclosed booths provide a controlled environment with features like:

- High-efficiency filtered intake doors to minimize dust and contaminants.

- Superior lighting systems for precise application.

- Options for pressurized or non-pressurized configurations based on your requirements.

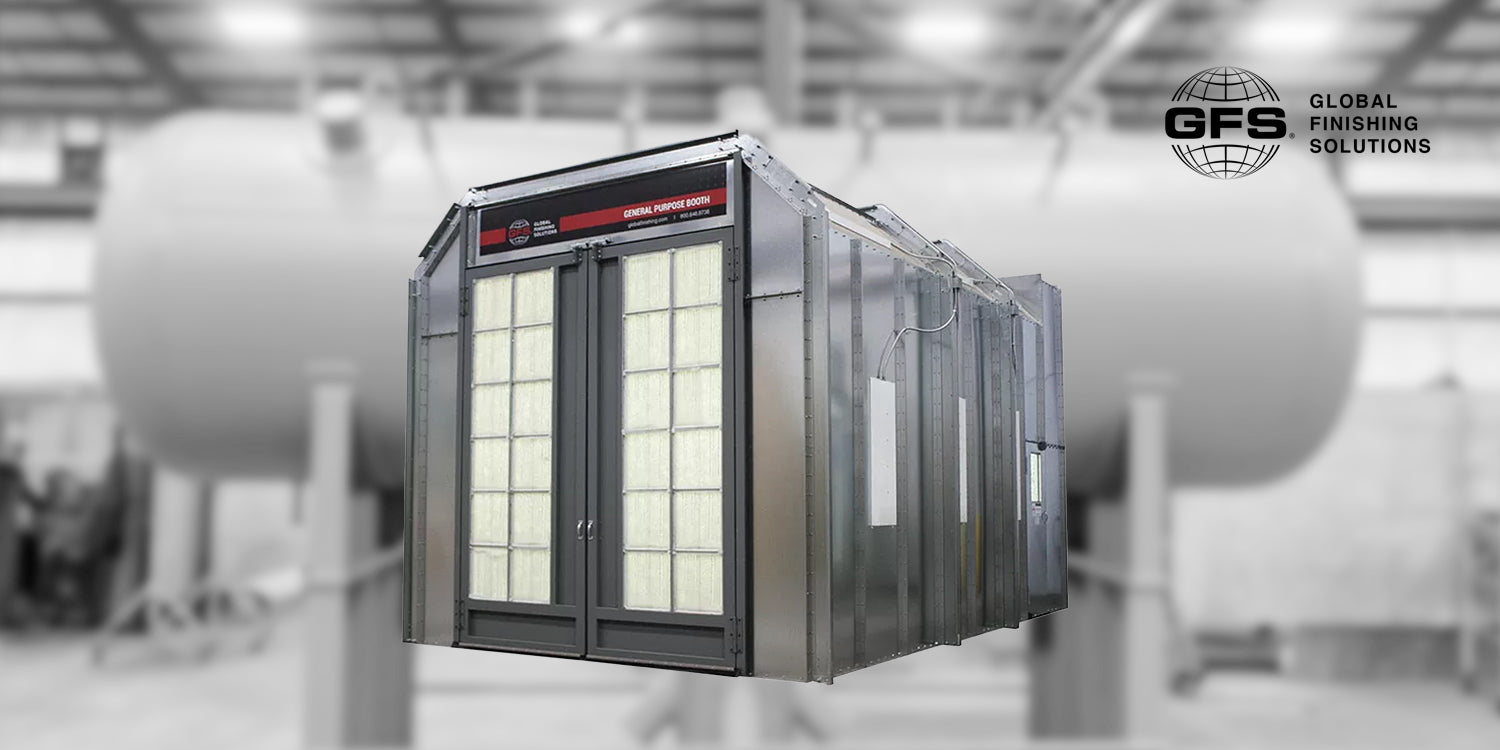

3. General Purpose Paint Booths

Designed for versatility, these booths are suitable for painting equipment, utility vehicles, and other industrial products. They offer:

- Pre-engineered models with excellent airflow and filtration systems.

- Customizable options for unique applications or larger-scale operations.

4. Dry Filter Booths

For industries requiring efficient overspray capture without water wash systems, dry filter booths are a cost-effective solution. They feature:

- Multi-stage filtration systems to handle various coating types.

- A range of standard, optional, and custom features to match your needs.

Key Factors to Consider When Selecting a GFS Booth

Choosing the right booth involves evaluating several critical factors:

1. Size and Configuration

Start by assessing the dimensions of the products you’ll be finishing. Ensure the booth can accommodate not only the largest items but also allow adequate space for operators and equipment.

2. Airflow Style

The airflow style significantly impacts finish quality. Options include:

- Crossdraft: Air flows horizontally across the product; suitable for basic applications.

- Downdraft: Air flows vertically from ceiling to floor; ideal for high-quality finishes as it minimizes overspray contamination.

- Semi-Downdraft or Side-Downdraft: Hybrid styles offering balanced performance.

3. Volume of Work

Consider your production volume. High-volume operations may benefit from automated features or larger booths with multiple workstations.

4. Custom Features

GFS specializes in tailoring booths to meet unique requirements. Whether you need conveyor openings, crane slots, or specialized filtration systems, GFS can engineer solutions that align perfectly with your operations.

5. Future Growth

Plan ahead by selecting a booth that can adapt to increased production demands or new finishing technologies.

The GFS Advantage

GFS booths are renowned for their durability, flexibility, and performance. Here’s what sets them apart:

- Modular Designs: Easily scalable and customizable to meet evolving needs.

- Superior Construction: Heavy-duty materials ensure longevity even in demanding industrial environments.

- Advanced Filtration Systems: Efficiently capture overspray while maintaining clean air quality.

- Energy Efficiency: Designed with sustainability in mind, reducing operational costs over time.

HMFT’s Role in Your Selection Process

At HMFT, we’re more than just a distributor of GFS products – we’re your partner in optimizing your liquid finishing operations. Our team of experts will:

- Assess your specific requirements and challenges.

- Recommend the most suitable GFS booth based on your needs.

- Coordinate with GFS engineers to customize features if necessary.

- Provide professional installation services and ongoing maintenance support.

With HMFT by your side, you can be confident that you’re investing in a solution that enhances productivity while aligning with your operational goals.

Conclusion

Selecting the right GFS paint booth is a critical step toward achieving superior liquid finishes while improving efficiency and sustainability in your manufacturing process. By considering factors like size, airflow style, production volume, and customization options, you can make an informed decision that meets both current demands and future growth opportunities.

Ready to upgrade your liquid finishing process? Contact HMFT today to explore our range of GFS booths and discover how we can help you achieve exceptional results with every finish.

FAQ

Q: What types of finishes are GFS paint booths suitable for?

A: GFS paint booths are designed for various liquid coatings, including water-based paints, solvent-based paints, primers, and topcoats.

Q: Can GFS booths be customized for unique applications?

A: Yes! GFS offers extensive customization options such as conveyor openings, crane slots, special filtration systems, and more to meet specific operational needs.

Q: How do I know which airflow style is best for my operation?

A: The choice depends on your finish quality requirements and budget. Downdraft booths offer premium finishes but may cost more upfront compared to crossdraft or semi-downdraft options.

Q: Are GFS paint booths compliant with safety regulations?

A: Absolutely! All GFS paint booths are designed to meet or exceed industry safety standards such as NFPA codes and International Fire Code requirements.

Q: How does HMFT support customers after installation?

A: HMFT provides ongoing maintenance services, repairs, training programs, and expert advice to ensure your equipment operates at peak performance throughout its lifecycle.